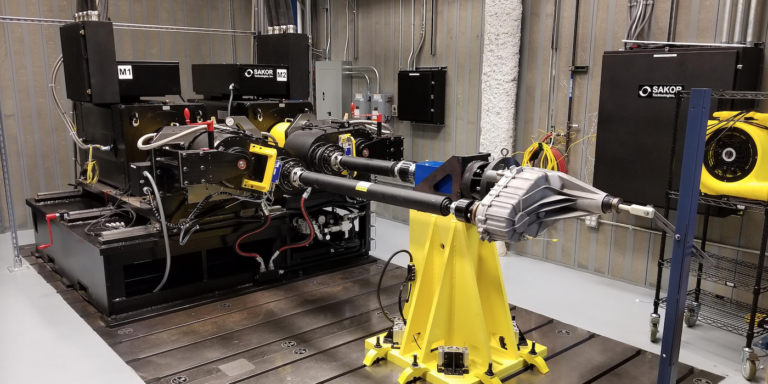

Dynamometer systems supplier, Sakor Technologies has delivered a test stand for testing clutches, transfer cases, and other torque transfer devices to an unnamed “major international provider” of powertrain components. The test stand will be used for testing torque transfer components in everything from small passenger cars to medium-sized industrial vehicles.

The system, one of six built for the customer, features dual 420 kilowatt dynamometers that can operate at up to 6,000rpm, with maximum continuous torque of 4,010Nm, and up to 150% overload for up to 30 seconds. The system is controlled by Sakor’s DynoLab data acquisition and control system, which provides fully automated test procedures for customer testing protocols.

According to Sakor, the dynamometers feature a unique adjustable output geometry, which enables users to configure the system to account for different input and output shaft centre lines and drop angles. This setup makes testing less expensive and safer and provides better data accuracy, as well as reducing system set up time.

The test stand also features a wide array of data acquisition channels, which can collect information on temperature, pressure, flow and speed. With controller area network (CAN) ports for communication with the customer’s smart controllers, the system can automatically shift the unit under test and also has the ability to directly control older devices that lack CAN communication capability.