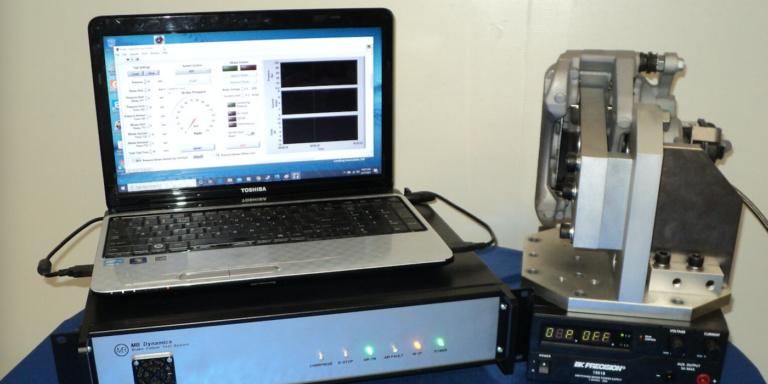

MB Dynamics has launched the Model BHP/EPB, a test bench for conducting R&D work on automotive brake hydraulic pressure (BHP) and electric parking brake (EPB) systems to support assessments of brake caliper and rotor assembly noise, useful service life, and other performance metrics. The test bench accurately measures and controls the hydraulic pressure and EPB power levels applied to brake calipers and drums during buzz, squeak and rattle (BSR) testing, under a variety of pressure conditions, in accordance with GMW16316, ‘Objective Brake Component Squeak & Rattle Test’ procedures.

The test bench also supports automotive brake caliper development and qualification testing procedures, which subject components to various automated brake fluid pressures & EPB controls. It further allows for mileage accumulation, performance cycling, and other forms of brake durability testing, with full manual control of brake caliper parameters, as required for troubleshooting, warranty and other R&D requirements.

The software used in the test bench software commands the system to perform either data acquisition and control of applied brake pressures, or to apply and/or release the EPB. Hydraulic brake and EPB caliper pressure levels can be varied according to timing diagrams, with automated cycling of different pressures, ramp rates, ON/DWELL times, OFF times, and total test times. The displayed test bench data can be saved and exported to an Excel or Windows-based PC clipboard.