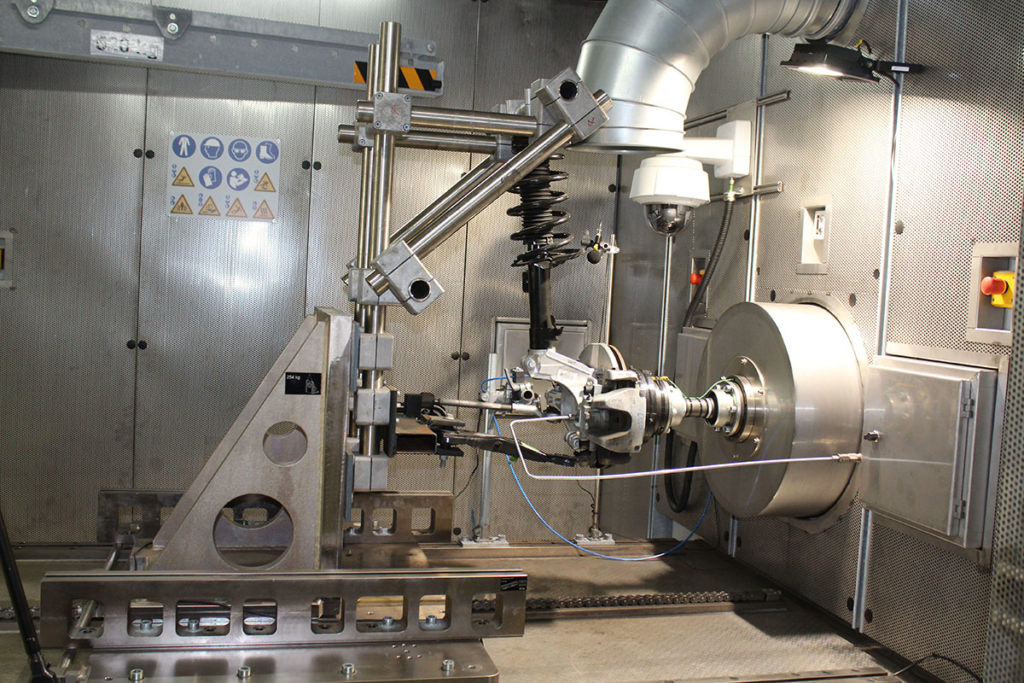

Horiba Automotive Test Systems has made its Giant Evo NVH brake dynamometer available for customer use at its Troy, Michigan facility. The dynamometer is the latest addition to the test facilities at this location available for conducting commercial test work for customers.

In addition to the normal range of industry standard brake test procedures, the Giant Evo NVH dyno enables advanced noise vibration harshness (NVH) investigations, with a precise environmental range of control to simulate real-world conditions on the road. Standard and customised test control procedures and data report formats can also be used to provide engineers with data that is critical to the design process.

“The availability of customer-specific testing in our facility is an alternative solution to customers having their own equipment at their facility,” said Keith Lewis, sales engineer at Horiba Automotive Test Systems. “We enable our customers to test their products in the controlled and repeatable environment that good testing practice dictates.”

Giant Evo NVH integrates with Horiba’s SPARC universal controller that uses control algorithms and intelligent control of brake actuators for a wide range brake test applications. This controller meets the demands of static to high-dynamic simulation brake testing procedures such as GM TIP and Ford L430, among others.

The dyno also features the Horiba Stars Brake Application Suite, which consists of ‘ready-to-go’ test procedures according to the relevant brake industry test specifications, including a range of industry standards for testing hydraulic, actuated disc and drum brakes. The suite contains performance tests as well as NVH procedures for passenger car brakes and light- to heavy-duty truck brakes.