Horiba MIRA has announced that Assured CAV, a proving ground it claims is Europe’s most comprehensive ecosystem for connected and automated vehicle (CAV) engineering and testing, is now fully operational.

The 350-hectare (850 acre) facility is located in Nuneaton, in the UK’s West Midlands region, and provides access to a diverse range of physical and virtual environments that replicate real-world scenarios to validate the challenges of implementing connected self-driving technologies.

The facility has been in development for four years at a cost of £100 million and includes full journey environments including high speed, urban, parking and CAV-enabled public road trial environments. Customers can also access simulation tools for virtual scenario testing, replicating the Assured CAV facilities and public road environments; proprietary technologies for recreating real-world objects that vehicles encounter on roads; a private 4G and 5G mobile network and ITS G5; and various ADAS robotic targets and supporting junction layouts.

Highway

The high-speed environment is titled Highway, and is a completely level facility with a 300m diameter dynamic platform to test vehicles at their limit. Features of this zone include fully configurable lane and junction markings; an asphalt surface within +/- 4mm flatness across the entire test area; and a 15 lane-wide central approach road.

The Highway area supports customisable scenario-based testing of merging, lane assist, platooning and evasive manoeuvres, which can be conducted to international regulatory protocols.

As an example use case, for ADAS and CAV testing, the west tangential approach is set up with a variety of centre line and lane edge temporary line marking to facilitate the testing and development of lane support systems across a wide range of use cases. Vehicle overtaking, undertaking and oncoming vehicle scenarios can also be undertaken at the west approach road.

In addition, the central approach can accommodate AEB testing for rear end, vulnerable road users and junctions, with an NCAP specification junction marked out utilising temporary line markings.

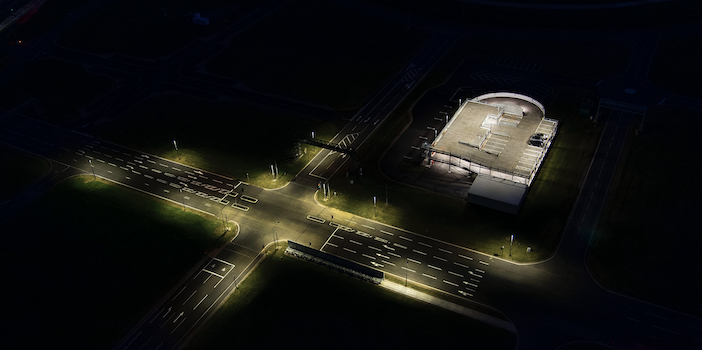

City

The City zone is a controllable and configurable, connected urban and sub-urban driving environment, with a mix of urban junction types and street furniture frequently experienced in cities. The zone enables the validation of complex automated driving systems and traffic scenarios under safe and repeatable test conditions.

For example, the master junction, equipped with connected traffic lights and using the facility’s private 5G network, has been designed to enable R&D of Green Light Optimisation systems. The connected traffic lights are also able to support the ITS G5 protocol.

Parking

Assured CAV also has a dedicated multi-storey car park that can be used to replicate real-world situations to support the development of self-parking systems. Options include restricted visibility, constricted manoeuvres and GPS drop-out in covered locations, while the indoor positioning system allows full GPS equivalency within the structure for accurate location and robotic target synchronisation.

The multi-storey car park can be used to facilitate the development of autonomous valet-parking systems, aided by challenging test scenarios including sensor deflection from ramps. Using the indoor localisation technology available in the car park, other actors, such as vulnerable road users, can be added into scenarios during manoeuvres. The lighting within the car park is configurable, to create sensor blindness due to varying lighting levels across an indoor car park.

Routes

The Routes section is a 500km network of CAV-enabled public roads, directly accessible from site. Equipped with a dedicated communications infrastructure, Routes also gives access to a full hierarchy of local and strategic road classifications.

Simulation

Horiba MIRA offers advanced simulation capabilities with a pre-configured ‘test-ready’ scenario database, tools to replicate weather and road conditions, and digital twins for physical tests on the proving ground and on the Routes section.

As well as digital twins, the facility offers physical twins using Horiba MIRA’s façade, road marking and street furniture technologies, with replication in Simulation and the Routes section. Users can enjoy authentic replication of the sensor signatures of masonry, vegetation and other physical materials.

Fast facts from the four-year construction process:

235,000m3 of earth was moved, all of which was reused on site

198,000m3 of earth was used in the construction of the Highway zone

37,000m3 of earth was used to create screening bunds

All test areas have zero gradient, both longitudinally and transversely

A 5.6km sustainable drainage system was created

20.5Ha of land has been set aside for natural regeneration