Following years of development, Bentley has announced a new carbon fibre wheel developed specifically for the Bentayga SUV. The 22in carbon wheel, engineered with composite supplier, Bucci Composites, is claimed to be the largest production carbon wheel in the world, and to reduce unsprung mass per wheel by 6kg, compared with the standard aluminium wheel of that size.

The carbon wheel has been subjected to TÜV standards, and Bentley says it is the first carbon wheel ever produced to pass all tests. The rim has undergone the most rigorous testing for non-metallic wheels according to the new TÜV standards, including biaxial stress testing, radial and lateral impact testing for simulating potholes and cobblestones, tyre overpressure, and excessive torque tests.

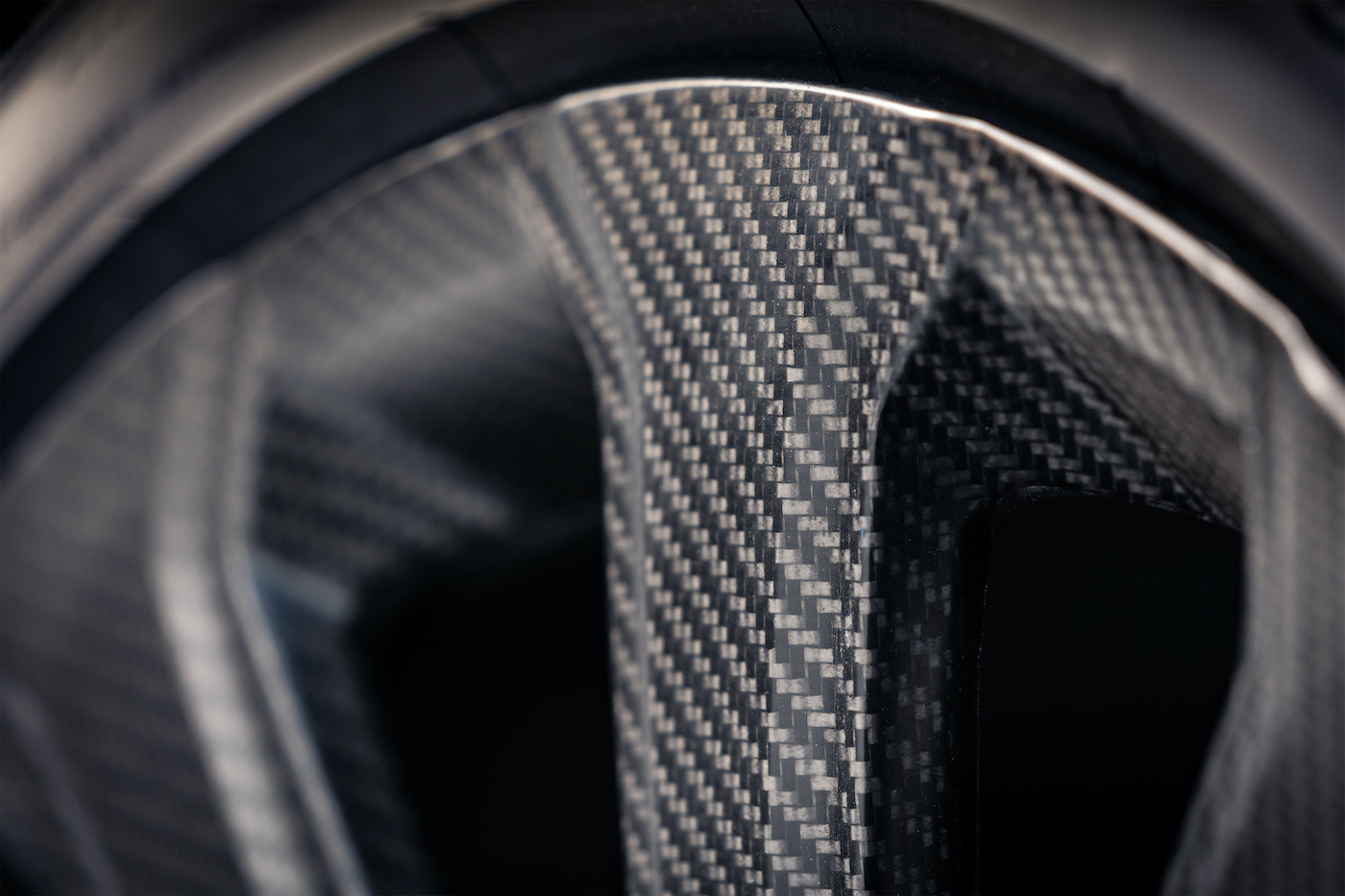

Bentley says that one of the most severe tests of the TUV requirements – the impact test – has shown the carbon rim to be “extremely safe” in addition to the performance benefits. After a severe impact, one which would crack or shatter an aluminium wheel, causing the tyre to collapse explosively, the carbon fibre rim allows a slow tyre deflation thanks to the strategic layering of fibre weaves. The weave pulls apart, leaving openings that allow gradual air loss rather than the instant deflation that would be suffered by an aluminium rim, allowing the vehicle to come to a controlled, safe stop. For the final signoff stage, the wheel was evaluated on the Nürburgring Nordschleife.

The carbon fibre wheel option also offers increased strength and stiffness compared with the standard Bentayga wheel options, while the reduction in unsprung mass leads to improved and more responsive braking. The 6 kg weight saving and the high stiffness afforded by the carbon fibre also mean a more stable, agile and consistent steering platform. In comparison, a forged aluminium rim can lose up to a degree of camber due to wheel flex, reducing grip and agility.

Since the stiffer carbon rim does not suffer from the same amount of bending as a metallic version, it allows for greater tyre stability and a more consistent contact patch thanks to a larger tyre support surface, as well as reduced tyre wear.

How it’s made

The rim manufacturing process involves the application of innovative concepts (covered by patents) combined with the use of high-pressure resin-transfer moulding (RTM). The materials and production parameters have been studied to ensure the repeatability of the product without affecting its quality.

The process involves the cutting of carbon fibre cloth into prescribed shapes. The weave segments are then stacked, heated and draped into a mould to create three-dimensional preforms. The preforms are collated and arranged into a larger mould before resin and hardener is injected throughout. After curing time at temperature, the component assembly is removed from the mould, and the final surfaces are machined to the correct finish, before polishing.