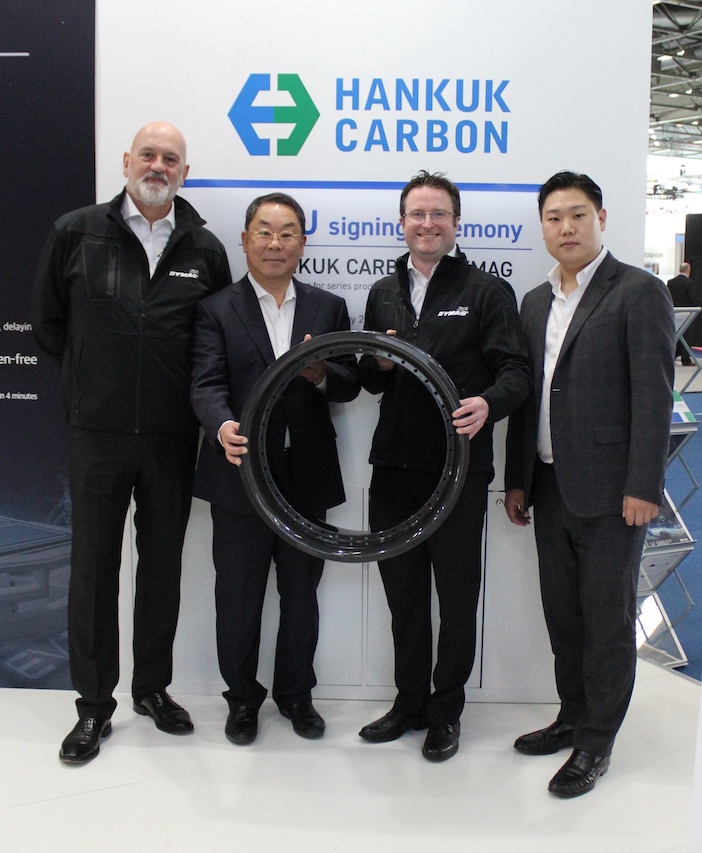

Carbon composite wheel manufacturer, Dymag, has entered into a partnership with Hankuk Carbon, a manufacturer of composite materials, to enable the mass production of high-performance carbon composite wheels for automotive OEMs.

The collaboration will leverage Dymag’s brand and experience in manufacturing lightweight carbon composite wheels for high-performance and luxury vehicle manufacturers, together with Hankuk Carbon’s expertise in advanced materials and industrialisation. The partners say that this combination of resources and technical expertise will accelerate time-to-market and enable economies of scale in the manufacturing of carbon composite wheels in series production, with a focus on a scalable and localised approach.

Dymag has been involved in wheel design since 1974, and in 2004 became the first company to commercialise carbon hybrid composite automotive wheels. Its wheels feature a carbon fibre rim with a forged aluminium or magnesium centre-piece. Hankuk Carbon has been producing composite materials, including carbon fibre textiles and prepregs, since 1984.

Together, the two companies will work to scale-up mass production of Dymag’s BX-F carbon composite wheel, available in sizes of up to 23in (rated to 1,000kg), with even larger sizes to follow. Dymag says the wheel technology brings advantages for automotive OEMs across all sectors, from luxury to high-performance, ICE to BEV, with weight savings of more than 50% over a traditional cast-alloy wheel, but with greater strength and durability.

This weight reduction can benefit vehicle range and NVH, especially for luxury EVs, while the reduced unsprung mass enables a reduced moment of inertia, and benefits for ride and handling.

Dymag CEO Tom de Lange said: “The price-point for these wheels will be appropriate for both luxury and performance-oriented versions of road cars, particularly the growing high-end electric vehicle market, thanks to Dymag’s technology benefits in improving EV range and NVH. For all automotive sectors, the dynamic, durability and aesthetic benefits of carbon composite hybrid wheels will become accessible to a larger number of consumers through OEM programmes.”