Bridgestone has invested in a new driver-in-the-loop (DiL) simulator at its EMEA R&D centre based near Rome, Italy. Complementing its virtual tyre development (VTD) capabilities, the new simulator forms part of the company’s efforts to fully digitalise the tyre development process. The simulator will enable Bridgestone to combine tyre and vehicle simulations with artificial intelligence (AI) technologies.

The tyre manufacturer has been working on VTD for around 10 years, and the DiL simulator will enable engineers to virtually reproduce tyre behaviour, vehicle interaction, and vehicle response in various conditions – combined with subjective input from test drivers. With the addition of AI technologies, the engineering team will be able to assess more tyre design options in less time, accelerating progress toward target tyre performance and the virtual experimentation of new design concepts.

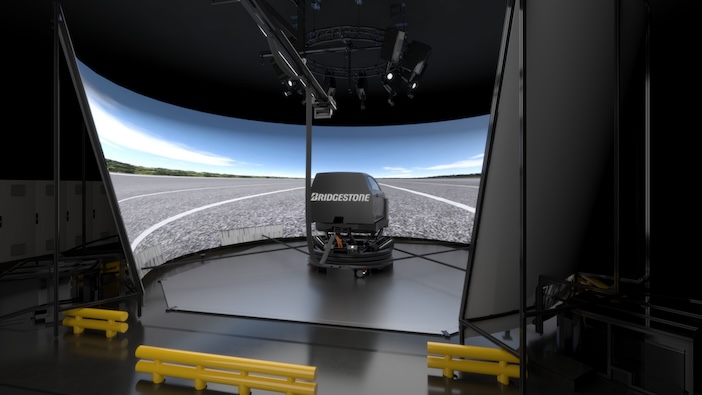

The dynamic driving simulator is being supplied by VI-grade, and is expected to be fully operative by the end of 2025. Bridgestone estimates that the DIL approach will be applied to up to 50% of its OE tyre development programmes annually. While today the DiL approach is mainly used by Bridgestone to assess dry handling, the company is working to expand both the tyre performance areas it can assess and the market segments it can be applied to.

“This investment in our internal DiL simulation capabilities is a major milestone as we build a comprehensive ecosystem for accurately predicting tyre performance in the virtual world,” stated Emilio Tiberio, chief technology officer at Bridgestone West. “It also gives us the capabilities to experiment with new and innovative combinations of designs and materials in a fully virtual environment.”