Penske Autosport is the latest professional motorsport team to acquire an Ansible Motion Delta S3 Driver-in-the-Loop (DIL) simulator, as the team mounts its title challenge in the 2024 FIA ABB Formula E Championship.

Launched just two years ago, the Delta S3 dynamic DIL simulator won the Development Tool of the Year category of the 2022 Vehicle Dynamics International Awards and has since been ordered by many teams in motorsport, including big names from F1, WRC, WEC, NASCAR, INDYCAR and Formula E, Honda Racing Corporation, Ford Performance, Stake F1 Team (Sauber Motorsport), Pratt Miller as well as at least one other unnamed Formula E team.

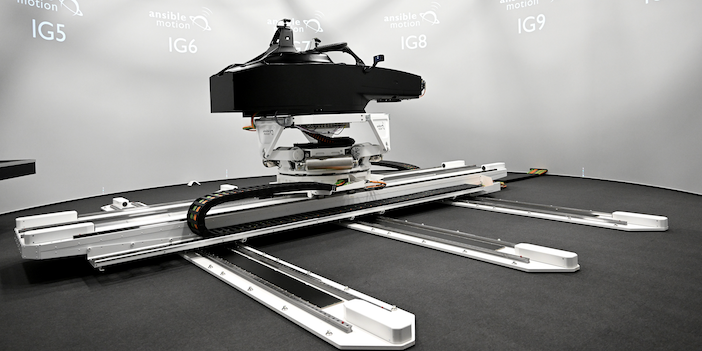

The simulator features 48K image rendering, a full 360° wrap-around screen for user immersion, a real Formula E cockpit environment (with quick-change function), a Stratiform six-degree-of freedom motion base with 360° yaw capability, a 4m by 4m ground plane motion envelope, and vision, audio and computer technologies. Penske Autosport will use these features to develop and improve its powertrain, software and race strategies for the all-electric world racing championship.

The Delta S3 was rigorously evaluated by Penske Autosport to confirm all areas of dynamic performance such as motion control and cueing, latency and frequency response. The team appreciated that installation of the simulator did not require floor reinforcements or significant groundwork, minimising installation costs and leading to its quick operational status.

Nicolas Mauduit, EVP at Penske Autosport said of the purchase, “There was no question about acquiring a Driver-in-the-Loop simulator here at Penske Autosport, since the benefits are significant. The question for us was finding the right simulator technology, and from a performance perspective Ansible Motion’s Delta S3 was the only simulator that checked all the boxes. Our drivers, Stoffel Vandoorne [2022 Formula E World Champion] and Jean-Éric Vergne [2018 and 2019 Formula E Champion] will rely on it, as well as our engineering team to maximise performance.”

The Delta S3 can replicate highly dynamic manoeuvres in real time with ultra-low latency, which is useful for the team’s drivers, and also for its engineers, who will use the simulator to validate torque mapping, electro-mechanical driver controls, and other specific areas that help them understand the sensitive vehicle inputs.

The Delta S3 can be connected with on-board ECUs for the powertrain and the eight CAN bus networks used in Formula E chassis. This offers engineers and drivers the ability to interact in real-time with Hardware in the Loop (HIL) and Software in the Loop (SIL) systems, replicating what they will experience in the real car.

Jean-Éric Vergne added, “Realism is particularly important. Some simulators look good on paper, but somehow fail to deliver a realistic experience. They can be nervous or ‘buzzy’ in a way that’s not quite right – and that’s ultimately not acceptable for working with our engineers to develop the car for maximum performance. Compared to other simulators, the Ansible Motion’s motion and visual cues are superior, matching exactly what I’d expect from a physics perspective.”

The wider picture

Penske Autosport also identified other technical and cost advantages from Ansible Motion’s role within the larger AB Dynamics group. Technical benefits include seamless integration reach into other areas and tools within the group, including the rFpro engineering-grade visual simulation environment. rFpro delivers accurate track surface modelling and visual content that, when coupled with Ansible Motion’s vision, motion and audio systems, enhances driver immersion and, ultimately, real-world physics correlation.

Penske Autosport’s rFpro-equipped simulator environment will allow trackside engineers to relay feedback to the team’s ‘mission control’ to easily update digital twin track models during race weekends. Necessary, on-demand changes – such as adding a new bump or kerb placement – can be achieved in around 30 minutes.