As the automotive sector works to reduce fuel consumption and CO2 emissions, key strategies are downsizing, cylinder deactivation and higher combustion pressures for combustion engines. However, since conventional and hydraulic mounts work passively, they are not always able to eliminate the types of disturbances created by such powertrain designs, which can increase engine vibrations. Vibracoustic has developed active motor mount systems to help solve this conflict by applying electronically generated compensation movements to neutralise the incoming vibrations and reduce noise by up to 20dB. The result is that vehicle manufacturers can implement fuel efficiency features without compromising on driving comfort.

The basic principle of the active motor mount systems lies in neutralising incoming sine wave vibrations by applying electrically generated compensation movements set at the same frequency. The appropriate setting of the phase position prevents the vibrations from being transferred into the chassis and felt inside the cabin, which ultimately increases the driving comfort for the passengers.

How it works

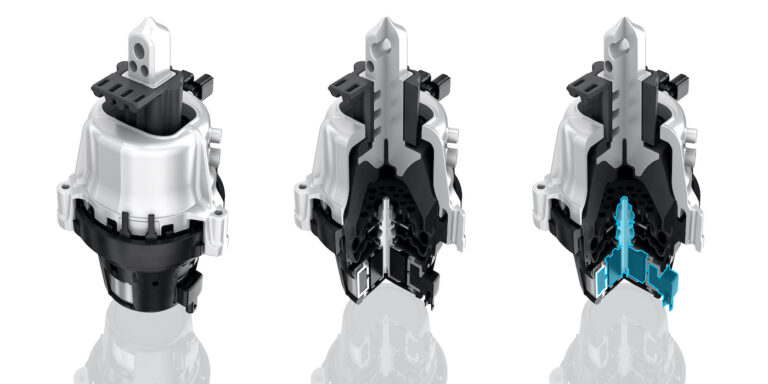

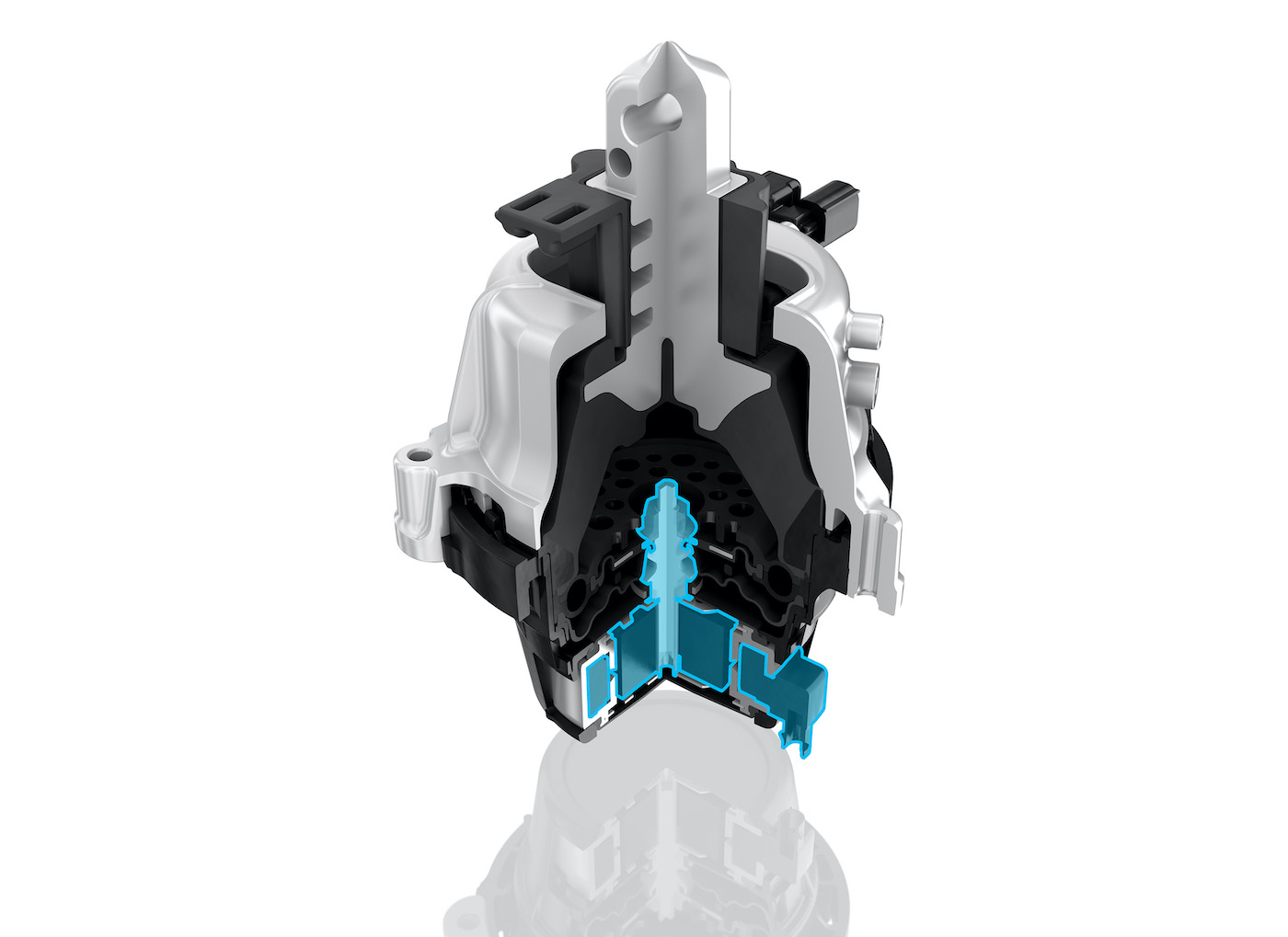

When low frequency, high-amplitude road excitations occur, the active hydro mount functions as a conventional mount, and an oscillation of the engine is damped by the movement of the liquid. When high-frequency, low-amplitude engine excitations occur, from idle to full load operations, the conventional hydro mount can no longer follow the quick movement due to the inertia of the fluid. Here the active function of the hydro mount comes into play, as it can operate the actuator up and down to control the internal pressure of the fluid and thereby adjust the dynamic stiffness of the mount, enhancing the vibration isolation performance while driving.

The active hydraulic motor mounts can work in a frequency range of 20-200 Hz and the generated compensation movements can lead to a noise reduction of up to 20dB under partial load conditions, and a reduction of up to 15dB under full load conditions.

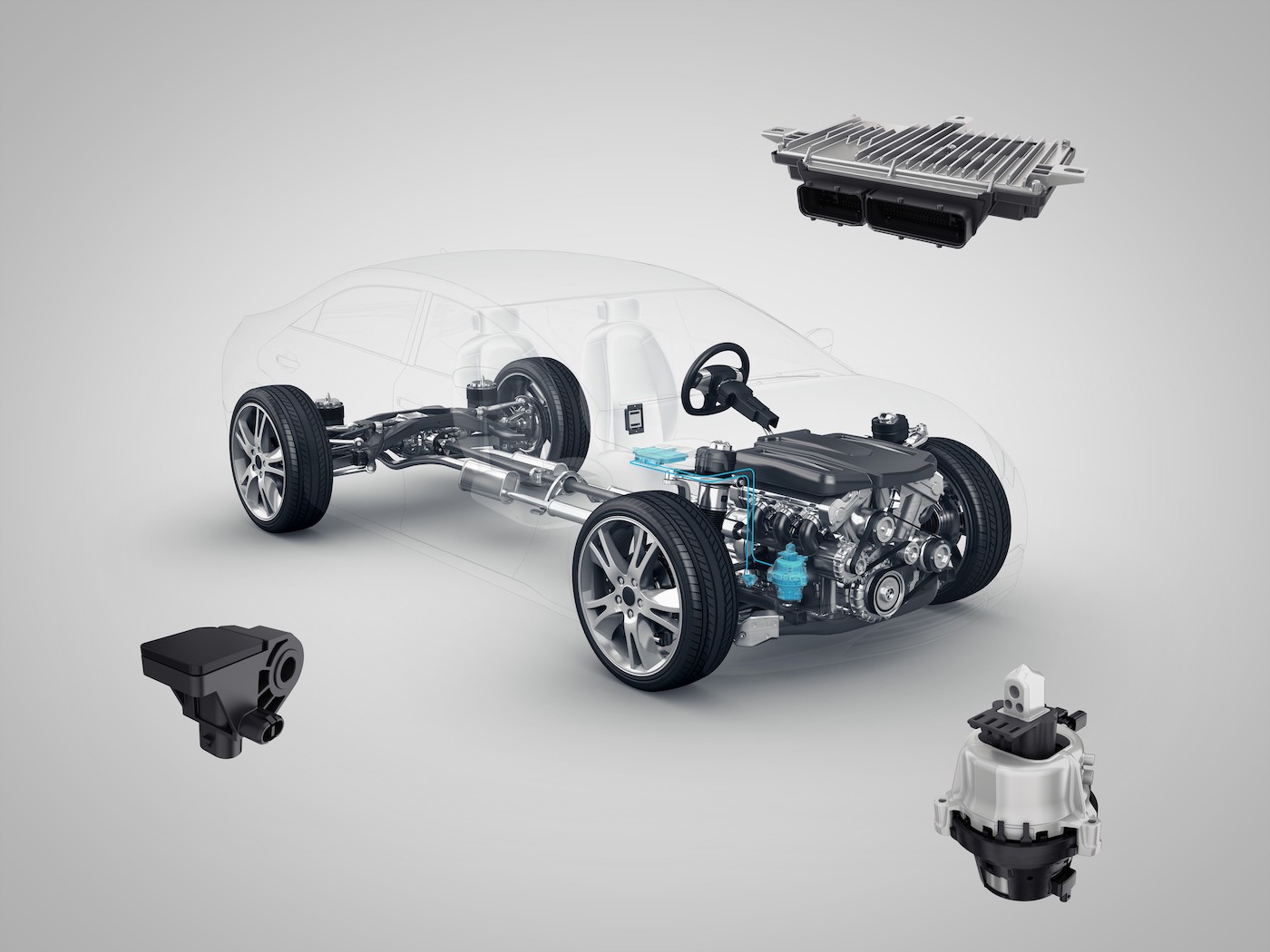

Active motor mount systems consist of a hydraulic motor mount with an actuator, an acceleration sensor and an electronic control unit (ECU). Whereas the acceleration sensor measures the excitations transferred into the chassis, the ECU calculates the required compensation movements in real-time and sends them to the actuator within the active hydro mount to cancel-out the incoming vibrations.

Vibracoustic is also able to realize the software integration of the ECU into the vehicle software environment. Active motor mount systems are most commonly used in three- and four-point longitudinal installation, but are also applicable to pendulum or central mounting systems, depending on transfer path analysis and direction of highest excitation. The benefits from active vibration control can also be also applied to high-frequency hybrid and electric motors.