Hyundai and Kia have unveiled ‘Uni Wheel’, a universal wheel-drive system that the companies believe will revolutionise the design of future mobility devices.

Uni Wheel is a functionally integrated wheel-drive system designed to increase the available space inside an electric vehicle (EV) by moving the main drive system components to the vacant space within the wheel hub. In doing so, Hyundai Motor and Kia have designed a completely new structure for the drive system.

In internal combustion engine (ICE) vehicles power is transmitted from the engine through the transmission and to the wheels via drive shafts and constant velocity (CV) joints. In EVs, the engine and transmission are replaced by a motor and reduction gear, but the final method of transmission to the wheels is the same.

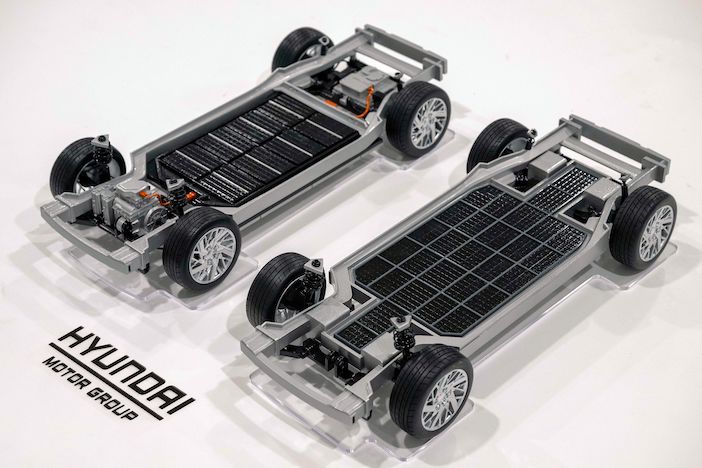

Uni Wheel opens new possibilities and enables a flat-floor configuration by moving the EV’s reduction gear inside the wheel hub, locating a compact individual motor close to each wheel, reducing the length of the drive shafts.

The system frees up interior space, enabling future mobility products optimised for various applications, such as Purpose Built Vehicles (PBVs).

How it works

Uni Wheel uses a planetary gear configuration consisting of a sun gear in the centre, with four pinion gears on each side and a ring gear surrounding the arrangement. Power generated by the motor is transmitted to the sun gear, which in turn engages the pinion gears to rotate the ring gear. This gear is connected to the wheel to drive the vehicle.

Uni Wheel’s pinion gears are connected to each other to form two linkages, and this multi-link mechanism enables Uni Wheel’s multi-axis movement to allow a wide range of suspension articulation.

A conventional drive system using a regular CV joint can suffer from a decrease in efficiency and durability as the angle of drive shaft deflection increases when travelling over bumpy, undulating surfaces. The companies say that Uni Wheel can transmit power with almost no change to efficiency, regardless of wheel movement, ensuring high durability and ride comfort.

When combined with electronic air suspension that can adjust ride height according to the driving situation, the power can be increased to stabilise the vehicle on rough roads, or decreased for power and stability in high-speed driving.

By moving the reduction gear to the wheel hub, Uni Wheel’s high reduction ratio delivers a significant torque output and allows for a more compact electric motor. With independent control of up to four efficient electric drive units, Uni Wheel also allows for what the development teams call “unprecedented levels of torque vectoring” to boost dynamic ability and deliver high levels of steering and driving stability.

“We are pleased to showcase innovative ideas that could become game changers in the future mobility market,” said Jongsool Park, Senior Fellow at Hyundai Motor Group’s Institute of Advanced Technology Development. “We will perfect the technology so that customers can experience mobility in a completely different and new way.”

Advancing future mobility

The Uni Wheel concept frees-up space within a vehicle that was previously unavailable to users. By relocating many components of the drive system to the wheel hub and downsizing the electric motor with no impact on performance, the extra space made available within the vehicle body can be used as additional cargo room, such as a larger trunk or a ‘frunk’.

It is also possible to move away from conventional seating arrangements designed around the driver, creating new interior layouts and designs for the era of fully autonomous driving. Utilising this space to improve battery capacity can also improve driving range, meaning users can achieve the range of a large EV without the physical size of the vehicle growing.

Hyundai and Kia say the Uni Wheel will also enable significantly increase passenger space in a vehicle. EV batteries are conventionally located low down in a vehicle’s body, which requires a raised ride height, often reducing passenger space in line with the volume of the battery. However, the Uni Wheel optimises battery packaging, minimising the loss of passenger space.

This will be a valuable feature for Purpose Built Vehicles (PBVs), which need to maximise interior space by offering a low, flat-floor design. The flat-floor platform enabled by Uni Wheel allows for strong flexibility and scalability when it comes to PBVs, enabling the design of various body types depending on the intended use case.

Uni Wheel is adaptable to all types of EVs, including regular passenger and high-performance EVs, as the system can implement the same powertrain and reduction gear functions required for conventional EVs.

In addition to vehicles of various sizes, Hyundai and Kia say that Uni Wheel can also be applied to other types of mobility devices, such as wheelchairs, bicycles and delivery robots. Depending on the requirements of these different forms of mobility, Purpose Built Vehicles (PBVs).

Uni Wheel can be scaled to work with wheel sizes as small as 4 inches and as large as 25 inches or more. In addition, Uni Wheel’s ability to move the rotation axis of the wheel could even make it possible to create forms of personal mobility that can climb stairs as smoothly as an escalator.

Hyundai and Kia are verifying the stability, efficiency and durability of Uni Wheel through various tests to perfect its development and the teams plan to continue their efforts to improve its efficiency by adjusting the reduction gear ratio, and upgrading the lubrication and cooling system.

Hyundai Motor and Kia have applied for and registered eight patents related to Uni Wheel in South Korea as well as the United States and Europe.