China-based automotive supplier, CITIC Dicastal, is planning to reveal several lightweight components at AMEE 2020 (the Shanghai International…

Browsing: Lightweighting

A new study by the UK’s Cranfield University has found that switching from aluminium to zinc alloys in the…

Mike Flewitt, CEO of McLaren Automotive, has confirmed that the company is further pursuing its…

The Ernst Gaßner Award is an initiative by Fraunhofer LBF that recognises outstanding achievements in structural durability and exceptional contributions in the development of safety-relevant, reliable lightweight components. This year saw the Darmstadt-based institute honour two winners in a video ceremony: Dr Yung-Li Lee of FCA, and Bruno Seufert of Daimler AG

Since 2002, the Fraunhofer Institute for Structural Durability and System Reliability LBF (Fraunhofer LBF) has…

Hot Form Quench (HFQ) technology can enable faster, less expensive high-volume automotive OEM production of lighter weight vehicle parts. The RACEForm project explains how it has developed an innovative aluminium manufacturing process project validated for high-volume automotive OEM applications

TRB Lightweight Structures has announced that it plans to open a composites manufacturing centre in Richmond, Kentucky,…

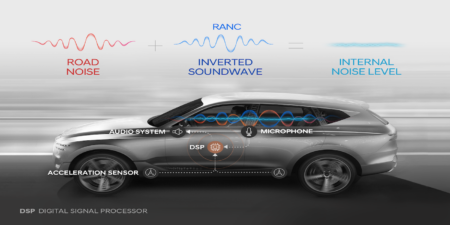

Hyundai Motor Group has developed a lightweight active noise-reduction system, which will make vehicle cabins quieter –…

Continental has developed an air spring system featuring an integrated polyamide plastic roller piston, which it claims represents a “groundbreaking step” towards reducing the weight of buses and trucks

Mazda has developed what it believes to be the world’s first cold-stamped vehicle body parts made from 1,310 MPa-class high-strength steel, an achievement that can result in lighter weight vehicle bodies, which in turn can contribute to improved vehicle handling, stability and fuel economy