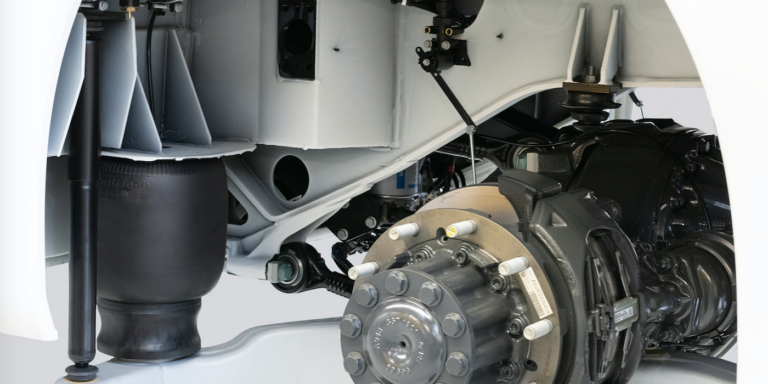

Automotive technology company, Continental has developed an air spring system featuring an integrated polyamide plastic roller piston, which it claims represents a “groundbreaking step” towards reducing the weight of buses and trucks. Continental is backing its claim with the example of one of its clients, bus manufacturer EvoBus, which is equipping its entire fleet of buses with the lightweight air spring system and reaping a weight saving of 2-2.6kg in each air spring module (compared with steel pistons) – adding up to a total 15kg weight saving for a two-axle urban bus.

The roller pistons are also said to deliver “outstanding” ride comfort thanks to the maximum utilisation of the inner air volume and their special design. Instead of steel or aluminium, plastic components made from polyamide are used in their construction, which helps reduce weight without compromising ride comfort. Continental has combined injection moulding and a reliable joining to enable the inner volume of the piston to be utilised to the full, aiding ride comfort.

“We are facing some tremendous challenges in the automotive industry, with business models and markets undergoing major and rapid upheaval,” stated Diethelm Bauch, who heads the air spring systems division for Continental’s commercial vehicles original equipment business. “Lightweight design can make a key contribution, especially when it comes to energy efficiency and CO2 emissions. I see no end to this trend. Our lightweight air springs have in one fell swoop given bus and commercial vehicle manufacturers a solution that offers much greater design flexibility. Plastic offers much greater design freedom and the capacity for customised, comfort-oriented design.”

Bauch added that the weight saving of the air springs his is a key advantage, especially in the e-mobility segment where the batteries themselves are very heavy and so all the other components need to be designed to offset the weight of the batteries and extend the vehicle range.

EvoBus is installing the air springs in its buses with a view to enhancing ride comfort, vehicle reliability, and to help the company meet the requirements of the EU’s Euro 6 emissions standard, which makes provisions for substantial reductions in pollutant levels for trucks and buses. The extra weight added by increasingly complex exhaust gas aftertreatment systems can be effectively offset by using lightweight components.

The air springs are also an easy retrofit option, with no need for any modifications to the vehicle interfaces.