Altair, a technology company working in the fields of product development, high-performance computing (HPC) and data analytics, has announced the winners of the 2020 Altair Enlighten Awards. These awards, now in their eighth year, are presented jointly with the Center for Automotive Research(CAR), to recognise the world’s best initiatives to reduce vehicle weight and meet emissions targets.

Presented in four categories, the 2020 Enlighten Awards winners include:

Full Vehicle winner: Harley Davidson Motor Company

Harley Davidson used electrification to improve the energy capacity of its Livewire electric motorcycle by 90%, while increasing the ratio of energy capacity to vehicle mass by 60%. In addition to further improvements, this initiative established mass and stiffness design and optimisation practices for future motorcycle programmes.

Runner-up: Nissan for its new Sentra 2020 platform, designed to improve safety and dynamic performance without increasing weight by using simulation to place the right materials in the right locations.

Module winner: Toyota

An industry first, Toyota created a free-standing, two-occupant injection-moulded back-frame with no moulded reinforcement for the 2021 Sienna. It consolidated 15 components into one part with one injection, driving down costs by 15%, reducing mass by 30% and improving safety performance two-fold.

Runner-up: ZF created the first-to-market electric park brake (EPB), with more than 75 million vehicles fitted with EPB for world roadways. The heavy-duty EPB offers a weight savings of 25 lbs or more for large trucks and SUVs when compared to conventional drum-in-hat park brakes.

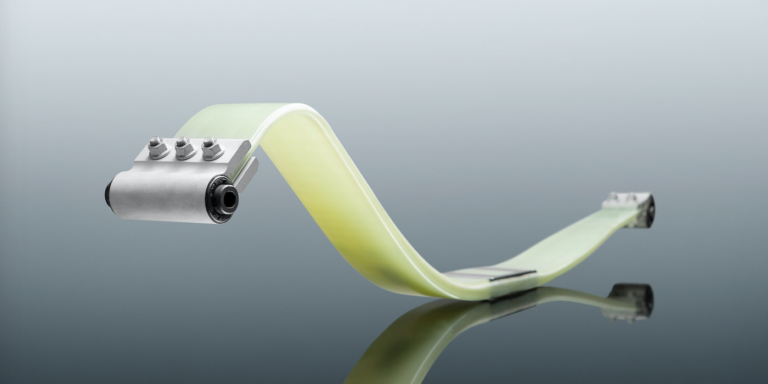

Enabling Technology winner: Mubea

Mubea developed a glass fibre-reinforced polymer (GFRP) Tension Leaf Spring with claimed weight savings of up to 75% compared to a standard multi-layer steel spring. The company used a scripted and automated workflow that begins from a parametrised spring model in which all spring parameters can be adapted.

Runner-up: DuPont’s BETASEAL bonded thermoplastic liftgates, for the use of BETASEAL X2500 structural adhesive, which quickly joins thermoplastic inner and outer panels and enables modular lightweight assembly. The company’s Magna thermoplastic liftgates bonded with BETASEAL X2500 structural adhesive have realized a 20-30% weight savings compared to welded steel liftgates.

Honourable mention: Mazda’s computer-aided engineering (CAE) multi-disciplinary design optimisation (MDO) methodology captures top technology trends by applying simulation-driven design and data analytics for product design.

Future of Lightweighting winner: Marelli

Marelli developed a new advanced sheet compression-moulded suspension steering knuckle that creates a claimed 25% mass savings compared to the aluminium version used on the Jeep Compass, and 50% savings compared to the cast iron version.

Runner-up: Nissan’s ultimate lightweight aluminium/carbon fibre reinforced polymer (CFRP) body side panel using topology design reduces weight by utilising a multi-material structure of aluminium and short fibre carbon fibre reinforced thermal plastic (CFRTP). Compared to conventional steel body side panels, it can reduce weight by approximately 50%.

“We are proud to offer the automotive industry’s only award dedicated to vehicle lightweighting and are thrilled to see how many advancements are made through the use of optimisation technologies,” said Richard Yen, Altair’s senior vice president, global industry verticals. “Each year the entries are more and more impressive, making it increasingly difficult to select the winners as entrants are making great strides in lightweighting, and using inventive approaches through simulation and materials.”