The UK’s University of Bath and Kistler have co-operated on a project to investigate how technology can be used to provide objective and repeatable analysis of the parameters of plug-in hybrid automotive propulsion systems. The research is intended to help automotive engineers optimise vehicle emissions and fuel efficiency without compromising performance and drivability.

According to the teams the main challenge was to be able to characterise the whole vehicle powertrain performance, such that laboratory conditions and on-road conditions could be accurately matched in real-time. This requires accurate analysis of powertrain inputs, outputs and responses, including torque and energy flows for the whole system.

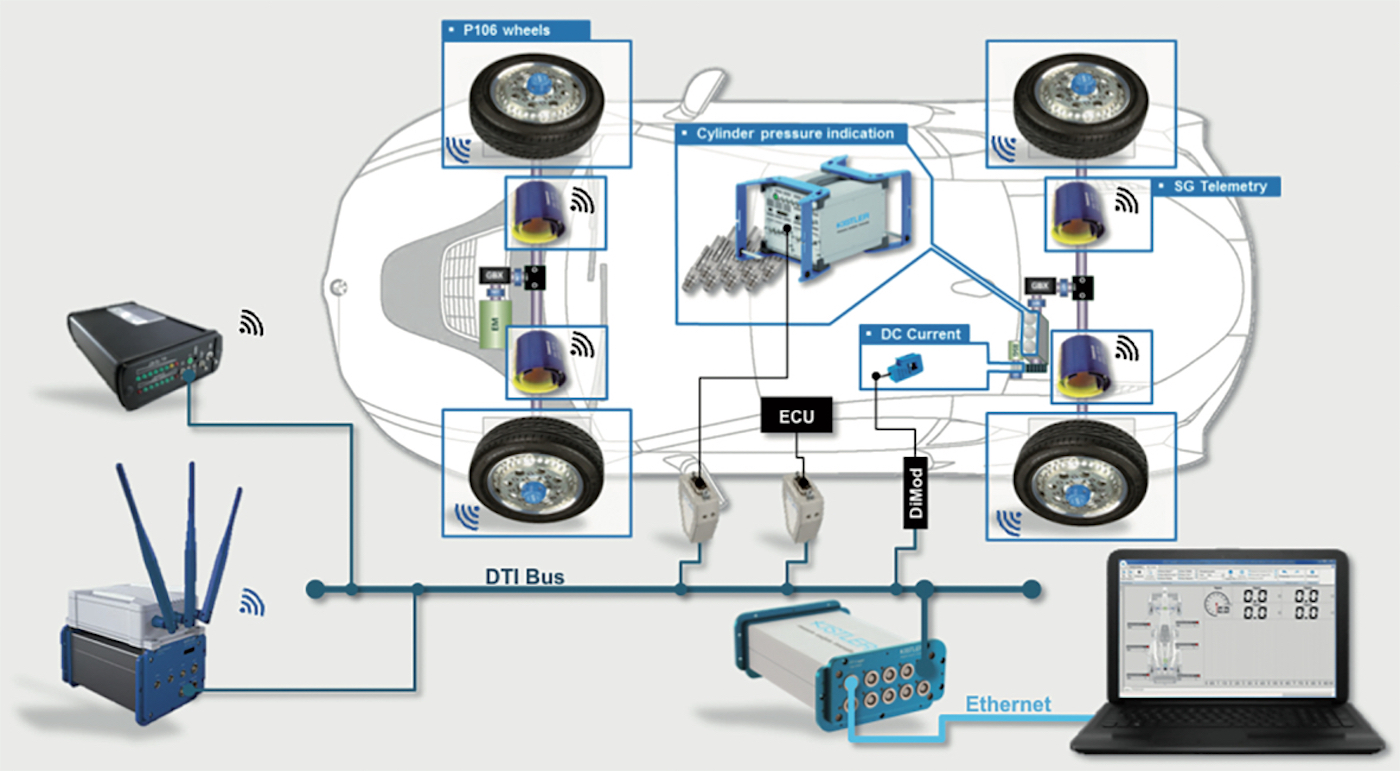

Extensive instrumentation was installed on the BMW i8 test vehicle, which is being used by the University as part of a UK government-funded project for defining future vehicle development processes, combining collaborative vehicle modelling with over-the-air, real-time data distribution. The instrumentation included a KiBox for measuring engine performance metrics and torque, Kistler wheel torque sensors for propulsion torque and braking force measurement, and instrumented drive-shafts for torque distribution and recuperation measurement.

From the data recorded in real-time and then post-processed, the vehicle propulsion system could then be analysed, with some surprising observations reported. In particular, strategies for good tip-in response, involving mechanical energy storage within the powertrain mechanics (via shaft wind-up) could be identified.

Future cooperation between Kistler and the University is planned, and this advanced testing methodology will be furthered with the opening of the University’s new £70m Institute for Advanced Automotive Propulsion Systems (IAAPS) in 2021.