Gordon Murray Group (GMG) has announced that it is leading a consortium project working to create a new generation of lightweight vehicle structures. The project aspires to create a new vehicle monocoque architecture that is lighter and stronger than many current structures, and 50% less carbon-intensive to produce – and to achieve this within a timeframe of just three years.

The initiative, titled ‘Project M-LightEn’ (Monocoque architecture – Lightweight and Low Energy), has received funding support from Innovate UK and the Advanced Propulsion Centre (APC). The venture is projected to create up to 160 new jobs across the Gordon Murray Group, and the other project partners: Carbon ThreeSixty, Constellium, and Brunel University of London.

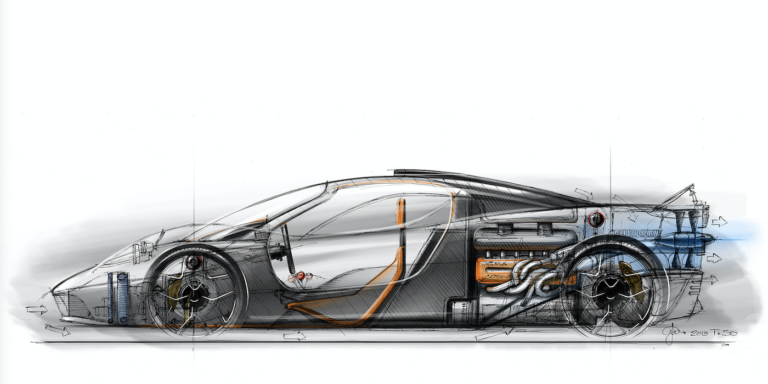

Gordon Murray Group will lead the project, working to research, design, build and validate a series of digital and physical monocoque prototypes. The target result is the validation of several new designs, which would pave the way for the development and industrialisation of innovative monocoque vehicle structures.

The consortium is targeting a reduction in vehicle lifecycle CO2 of a third or more, and will use AI to optimise designs, while also developing new materials and advanced manufacturing processes. Constellium and Brunel aim to contribute STEP-enhanced ultra-high-strength extrusions made from 80% recycled UK consumer scrap aluminium within the monocoque structure. Meanwhile the production of lightweight carbon fibre composite components by Carbon ThreeSixty is aiming to achieve near-zero-waste levels in manufacturing and low weight through the company’s highly precise ‘tailored-fibre-placement’ production process.

Indeed, with its vehicles already being lightweight, Gordon Murray Automotive (GMA) believes that if the project is successful then its vehicles could have the lowest lifecycle carbon footprint of any supercar on the market.

Jean-Phillipe Launberg, GMG’s strategy and business director said of the announcement: “The potential for this project is exciting to Gordon Murray Automotive as the company constantly strives to utilise the very latest materials, technologies, and processes to produce its driver-focused supercars. “Alongside Gordon Murray Automotive’s niche supercar application, Project M-LightEn will enable decarbonisation across the wider automotive industry by shortening and de-risking the path to market for innovative new materials and processes.”

The first phase of the project is already under way, exploring new materials and ‘joining’ techniques. From late 2027, developments from M-LightEn are projected to be available for low-volume commercial use, with larger, mainstream applications rolled out thereafter.

“This project represents an excellent opportunity to exploit the high-strength extrusion aluminium alloy technology developed in the EPSRC strain-enhanced precipitation in aluminium (STEP Al) programme,” added Prof Geoff Scamans, Professor of Metallurgy at Brunel University of London. “The M-LightEn project will use the highest-performing aluminium extrusion alloys formulated from recycled end-of-life aluminium using novel thermomechanical processing techniques developed in this five-year programme.”