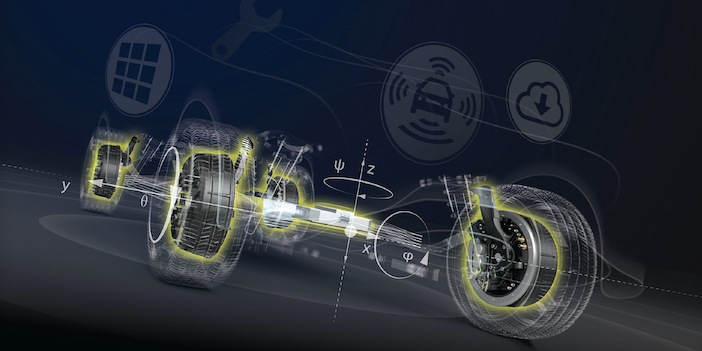

Elaphe and McLaren Applied have entered into a partnership to create what they have identified as a new vehicle segment of highly efficient and hyper-responsive electric vehicles (EVs). The companies are collaborating to provide an in-wheel propulsion system, coupling McLaren Applied’s inverter technology with Elaphe’s direct-drive in-wheel motors and control software, and multiple-wheel drive controls and vehicle controls. The partners say the combined in-wheel propulsion system offers best-in-class long-range cruising efficiency and vehicle controllability, with a torque response claimed to be five-times faster than that of existing systems.

According to Elaphe, its in-wheel propulsion system technology has demonstrated energy efficiency of more than 97% during tests on vehicles such as the Lightyear Zero and Aptera. The in-wheel technology has torque density of up to 460Nm/litre and 100Nm/kg and takes advantage of the high control bandwidth of each wheel to enhance safety and the software-defined driving character of a vehicle.

McLaren Applied has broad experience in high-performance power electronics, having supplied inverters for the McLaren P1 in 2012 and for Formula 1 and Formula E cars since 2013. McLaren Applied has brought this technology to the wider automotive market with IPG5, its next-generation 800V Silicon Carbide (SiC) inverter. IPG5 offers gravimetric and volumetric power density of 90kVA/kg and 130kVA/L, respectively, variable switching frequency, and a claimed efficiency of up to 99%. This inverter is designed to improve overall vehicle efficiency and can be used to tune driving dynamics.

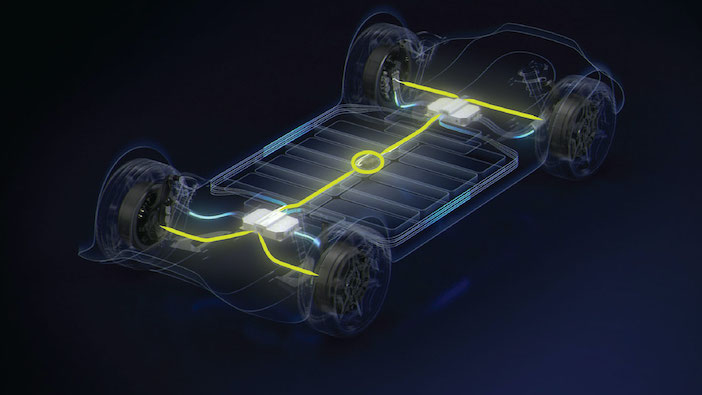

The technologies will be combined in an in-wheel propulsion system that couples McLaren Applied’s inverters with Elaphe’s direct-drive in-wheel motors and vehicle controls. Together, say the companies, the in-wheel system will enable ‘significant’ space and weight savings for OEMs, as well as reduced vehicle energy consumption.