Altair, a specialist in computational intelligence, has announced its involvement in the £5.8 million Performance Integrated Vehicle Optimization Technology (PIVOT) project, supported by Innovate UK and the Advanced Propulsion Centre (APC). The project aims to revolutionise vehicle manufacturing by creating lighter, more sustainable components, which will be aided by Altair’s cutting-edge artificial intelligence (AI) and simulation capabilities.

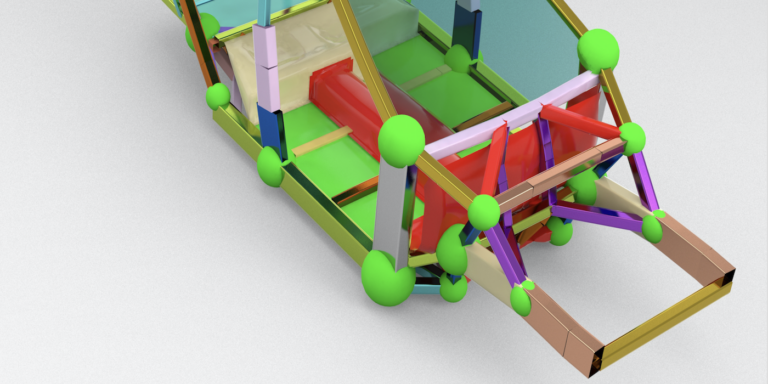

Led by Sarginsons Industries (an aluminium foundry in the UK), the PIVOT project brings together partners including Altair, Aston Martin, Brunel University London, and metal recycling experts GESCRAP. The partners will work to develop software that combines casting simulation, topology optimisation, and AI, which will enable organisations to design components optimised for weight, structural performance, and manufacturability. These goal is to enable cast aluminium structures that are up to 30% lighter in weight while still meeting performance requirements.

“This collaboration demonstrates how our AI-powered engineering technology enables manufacturers to develop more efficient vehicle components, cutting down on weight and drastically reducing environmental impact,” said Sam Mahalingam, chief technical officer, Altair. “We are proud to work with like-minded organisations to showcase how innovations in manufacturing contribute to a more sustainable automotive future.”

About PIVOT

Funded in part by a £2.9 million government grant from Innovate UK and APC, the PIVOT project will focus on using 100% recycled aluminium to reduce embedded carbon emissions in vehicle components by up to 95%. By overcoming mechanical weaknesses inherent in recycled aluminium through advanced grain refinement techniques developed by Brunel University London, PIVOT will make it possible to use secondary alloys for cast structural applications such as vehicle chassis systems.

“PIVOT represents a huge step forward for the casting industry,” said Mark Nunan, managing director of Sarginsons Industries. “With Altair’s state-of-the-art technology, we are pushing the boundaries of what’s possible, creating components that are not only lighter and stronger but also significantly greener.”

The PIVOT project will demonstrate how AI, recycled materials, and advanced casting processes can reshape vehicle manufacturing while reducing environmental footprint. The project is expected to enable OEMs and foundries to adopt more efficient and sustainable production methods.