Vibracoustic, a company specialising in automotive noise, vibration, and harshness (NVH) technologies, has revealed that it is developing new systems specifically for commercial vehicles with low- and zero-emissions powertrains. This vehicle sector is growing in focus as companies and the public are seeking for the transportation of goods and people to be more sustainable. However, similar concerns to those of electric cars are arising in the commercial vehicle sector, albeit at a bigger and heavier scale: from the distinct acoustic character of electric motors and inverters, to the additional weight and safety considerations of battery packs.

Electric motors produce a wide range of frequency, including high-frequency excitations of more than 600Hz, which can be disturbing for the human ear, particularly when coupled with the other noises which are left unmasked by the quieter powertrain.

Vibracoustic’s engineers identified the specific requirements for e-motor mounting and then developed solutions that meet the isolation and decoupling requirements of commercial vehicle (CV) OEMs. One solution, developed to promote comfort while addressing the high frequency excitations in electric CVs, is the ‘double isolation’ system. This system uses two layers of rubber components: one between the e-motor and subframe, the other between the subframe and chassis.

This construction means that the subframe is used as a blocking mass whose inertia – with the correctly designed vibration technology system – can reduce the transmission of higher-frequency vibrations or structure-borne noise. The use of double isolation is particularly relevant for application in CVs such as e-buses, in which a high number of passengers are exposed to those excitations.

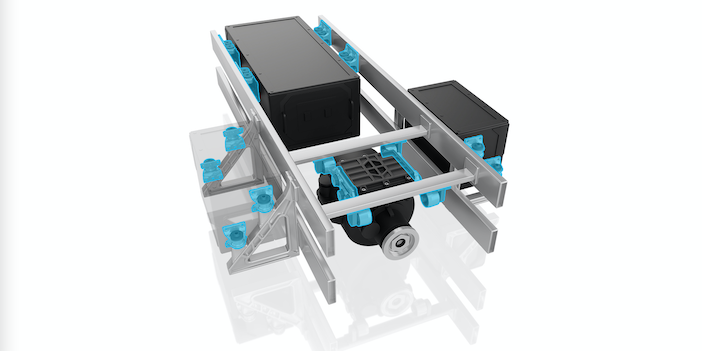

Battery packs have also been considered. Whether considering a fully electric, hybrid or fuel-cell CV powertrain, mounting and protecting the battery packs effectively is a critical consideration. These packs can weigh from 100kg to 6,000kg, with challenges linked to weight, mounting, crash loading and NVH. The Vibracoustic team has designed mounting solutions to meet OEMs’ needs for design, load and durability.

The battery-pack mounts must minimise the transfer of road excitations to the battery pack, including compensation for any deflection or movement of the chassis or vehicle structure. They must enhance structural integrity and overall frame stiffness, especially if the battery is an integrated element of the chassis. Vibracoustic says its CV mounts are designed to accommodate high travel, thereby ensuring stability and protection in operational conditions. Furthermore, the battery mounts play an important safety role as they help to reduce forces in an impact, acting as a robust energy absorber and dissipator.