An important element of achieving passenger comfort is ensuring the vehicle has good insulation from structure-borne sound. Switchable engine mounts are a useful tool, linking the powertrain to the body and serving to reduce road-induced engine vibrations, while also insulating against engine-induced vibrations to prevent them from being transmitted to the body and cabin.

However, Continental has developed an electronically switchable engine mount that will be fitted to the latest generation of a premium-segment sports sedan being launched by an as-yet unnamed ‘German premium-segment car manufacturer’.

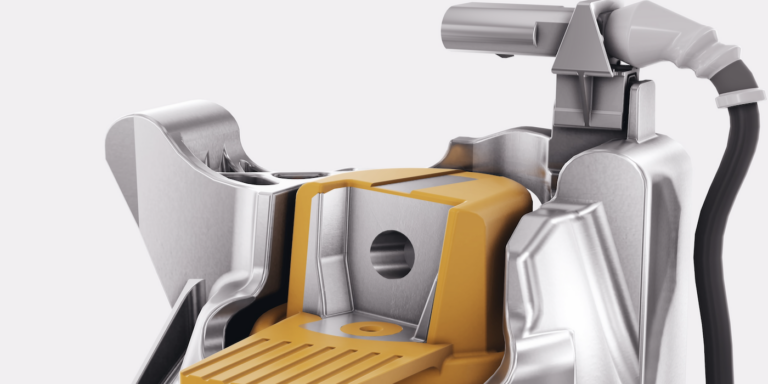

“A solid connection – that is, a high degree of rigidity – between the engine and body ensures excellent vehicle dynamics. But to ensure maximum ride quality, the rigidity needs to be low. This conflict of objectives is resolved by a switchable engine mount, which adjusts the required rigidity to individual requirements by means of an electromechanical shift actuator, thereby providing the perfect balance between extreme sportiness and maximum comfort,” explained Meinert Holst, project manager at Continental’s ContiTech Vibration Control division.

The electromechanical shift actuator on the engine mount adjusts the hydraulic properties of the engine mount such that, through the absorption effect, the dynamic rigidity of the mount when the engine is idling is less than the static rigidity, which helps to reduce the transmission of structure-borne noise.

According to Continental, the engine mount is around 10% lighter than standard variants, which also helps to save fuel.