According to GKN Driveline, three quarters of the new production-ready models launched at the 2017 Geneva Motor Show feature technologies supplied by the company. The UK-headquartered developer and manufacturer of driveline systems supplied constant-velocity joints, sideshaft systems, propshafts, all-wheel drive torque management solutions and eDrive technologies to a claimed 74% of the new production cars on display.

Two of the fastest rear-wheel drive supercars launched at the Geneva show will deliver their power through GKN’s lightweight rear sideshafts, which offer driveline efficiency and minimal component packaging requirements. Elsewhere, the BMW i8 Protonic Frozen Black will feature GKN’s two-speed eAxle driving the front wheels. The multi-speed eDrive delivers peak drive torque of 2,800Nm in a package that weighs 27kg and a claimed efficiency of 97%.

Front sideshafts from GKN Driveline will be supplied to the four-wheel drive model variants of two new premium models, while the company’s SX6 constant-velocity joint will appear in a new supermini. The SX6 joint uses GKN’s trademark ‘Countertrack’ technology, which features sets of opposed ball tracks to reduce packaging size and increase efficiency. The high steering angles that can be achieved also help to improve the car’s maneuverability.

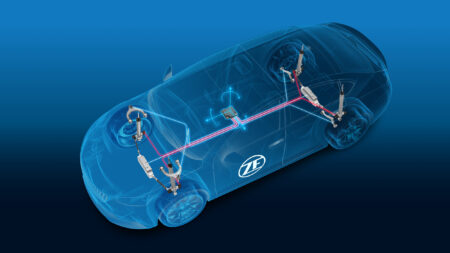

GKN Driveline’s Electronic Torque Manager (ETM2) LSD system will be supplied in tailored applications for a range of new models, including high-performance variants of a luxury SUV, premium estate car and a plug-in hybrid. The ETM2 system continuously adapts to both the driver’s demands and the amount of grip available at each individual wheel.

The latest GKN Driveline innovations were also showcased at Geneva. The ‘Twinster’ intelligent twin-clutch torque vectoring system will be supplied to an all-new road car, following its applications in the Range Rover Evoque, Land Rover Discovery Sport, Ford Focus RS, plus a range of General Motors vehicles. Meanwhile, GKN’s expertise in supplying complete all-wheel drive systems to manufacturers will be showcased in an all-new SUV.

GKN Driveline’s SVP of engineering and technology, Dr Ray Kuczera said, “We design, develop and supply driveline technologies for over 90% of the world’s car manufacturers, and the new production models at Geneva this year showcased a great cross-section of our capabilities across a wide range of vehicle applications. From high-efficiency, cleverly-packaged driveshafts to innovative all-wheel drive disconnect and high-performance torque vectoring solutions, GKN leads the world in vehicle driveline systems.”