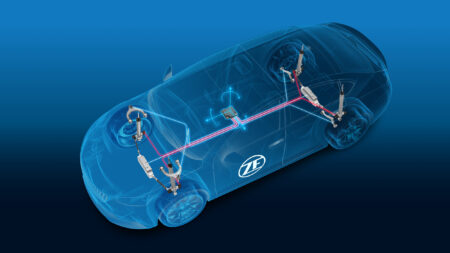

GKN Automotive has launched a standardised range of intelligent, highly integrated “3-in-1” systems for pure electric and plug-in hybrid vehicles, intended to offer reduced costs and increased efficiency. The systems integrate an electric motor, inverter and single-speed transmission module that scales-up torque, with the inverter retaining its own separate housing for ease of serviceability. The company’s Automotive Spice Level 2- and 3-certified software engineering processes enable it to manage the system’s complete integration. According to GKN Automotive, its intelligent standardisation strategy enables three families of electric drive to cover all mass-market torque requirements.

Hannes Prenn, COO of GKN Automotive ePowertrain said, “Standardising these systems will make electrification more affordable and will enable OEMs to offer consumers highly optimised e-mobility at the right price.”

GKN Automotive’s ‘Family 2’ eDrive system is already production-proven with a number of premium automotive brands. It provides peak torque of 1,800 – 2,700Nm and is suitable for A-, B- and C-segment applications. The Family 3 eDrive system covers C- and D-segment applications with peak axle torque of 2,700 – 4,100Nm, while the Family 4 eDrive system provides 4,100 – 5,800Nm for D-segment and large vehicle applications. Intelligent standardisation of the company’s own electric motor and inverter modules will further reduce system costs.

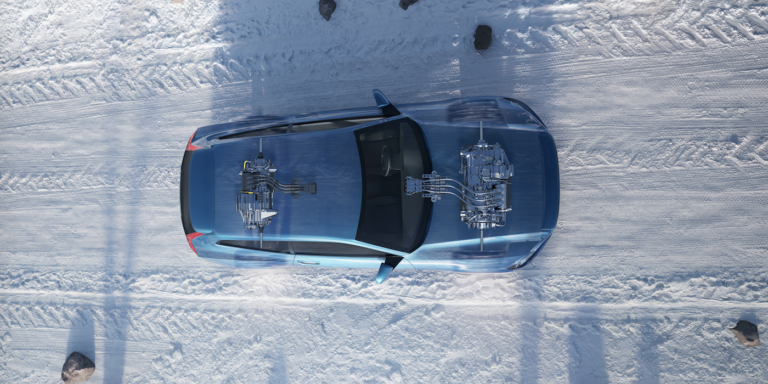

The company states that industry forecasts indicate that by 2026, one in every 10 vehicles sold worldwide will be a battery electric vehicle and that the high efficiency of P4 electric axle drive architectures will make them central to most pure electric and plug-in hybrid strategies. To provide the best balance of cost and performance, single-speed systems are expected to account for 94% of P4 eDrive volumes, says GKN.

P4 electric drive architectures connect the motor directly to the vehicle’s axle, making it more efficient and cost-effective than P2 and P3 systems that hybridise the main transmission. P4 systems send torque directly to the wheels and recover energy directly from the wheel when braking, with the electric drive systems integrating the inverter and electric motor into a compact transmission module that applies torque to the axle.