Continental is setting up a 50/50 joint venture with system supplier Aft Automotive, to manufacture couplings made of high-performance plastics as a replacement for lines and hoses. The partners see this development as a key part of future mobility, for hybrid and electric vehicles, as well as IC engines, with benefits in terms of vehicle weight as less hardware and fluids are required.

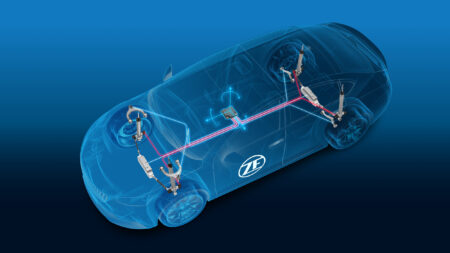

Unlike conventional vehicles, electric vehicles require multiple cooling circuits with sophisticated thermal management. Batteries in electric vehicles achieve optimum operating efficiency at temperatures between 20 and 40°C, a temperature span that enables long ranges, allows the batteries to work efficiently, and extends battery lifetimes. For that reason, in similar fashion to drive and power components, the batteries have to be either cooled or heated, depending on the outside temperature. That results in complex circuits that increase the demands on the individual components.

According to Continental and Aft, the right mixture of rubber, polyamide and aluminium materials and a rethought line geometry ensure the system has adequate inherent stability. Special lines and couplings made of high-performance plastics are being developed to ensure this.

Line systems are often made of rubber or stainless steel, but for vehicles with hybrid drives or electric motors, there is a growing trend towards replacing rubber with premium technical plastics. This change has allowed the developers to achieve further weight reductions while also improving performance: plastic components reduce vehicle weight and thus help lower fuel consumption and cut CO2 emissions. At the same time, the downsizing of space in IC engines is changing the demands on connectors and lines because lighter, quieter and higher-power drives result in increased pressure and thermal loads. For example, auxiliary unit components in the latest generation of IC engines have to withstand continuous temperatures of 160°C for over 3,000 hours, with temperature peaks of up to 210°C. High-performance plastics such as heat-stabilised polyamide are able to meet these demands, according to the partners.