Lotus has unveiled an innovative lightweight chassis technology that will be integrated into a new architecture for its forthcoming Type 135 electric sports car, scheduled for launch in 2026. The structure has been developed through Project LEVA (Lightweight Electric Vehicle Architecture), Lotus’s research programme to accelerate the development of all-new lightweight structures for next-generation battery electric vehicles.

A headline figure revealed for the chassis is that the rear subframe is 37% lighter than that found on the Lotus Emira V6. Such an advance has given Lotus the confidence to promote the architecture as the ‘blueprint’ for the next generation of electric sports cars, for future Lotus vehicles, and for the Lotus Engineering consultancy to commercialise to third parties.

The Lotus-developed vehicle architecture is versatile, being fully adaptable to provide a platform for a range of EVs with variable layouts, wheelbase lengths, battery sizes and configurations.

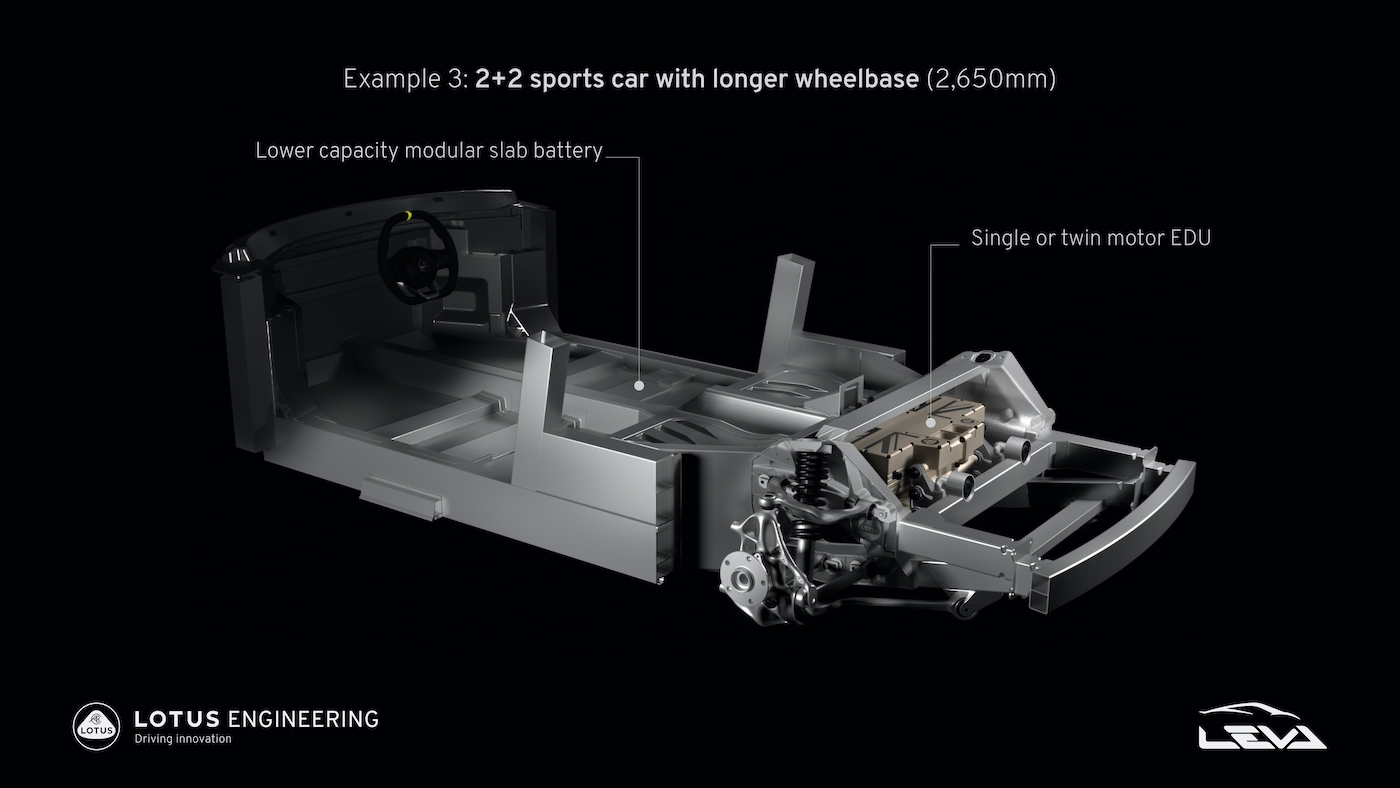

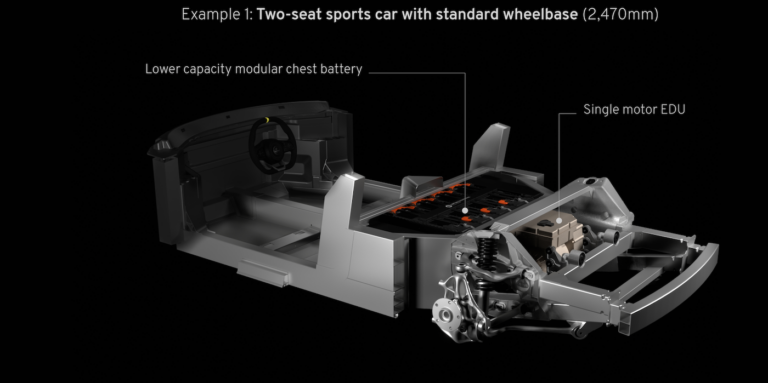

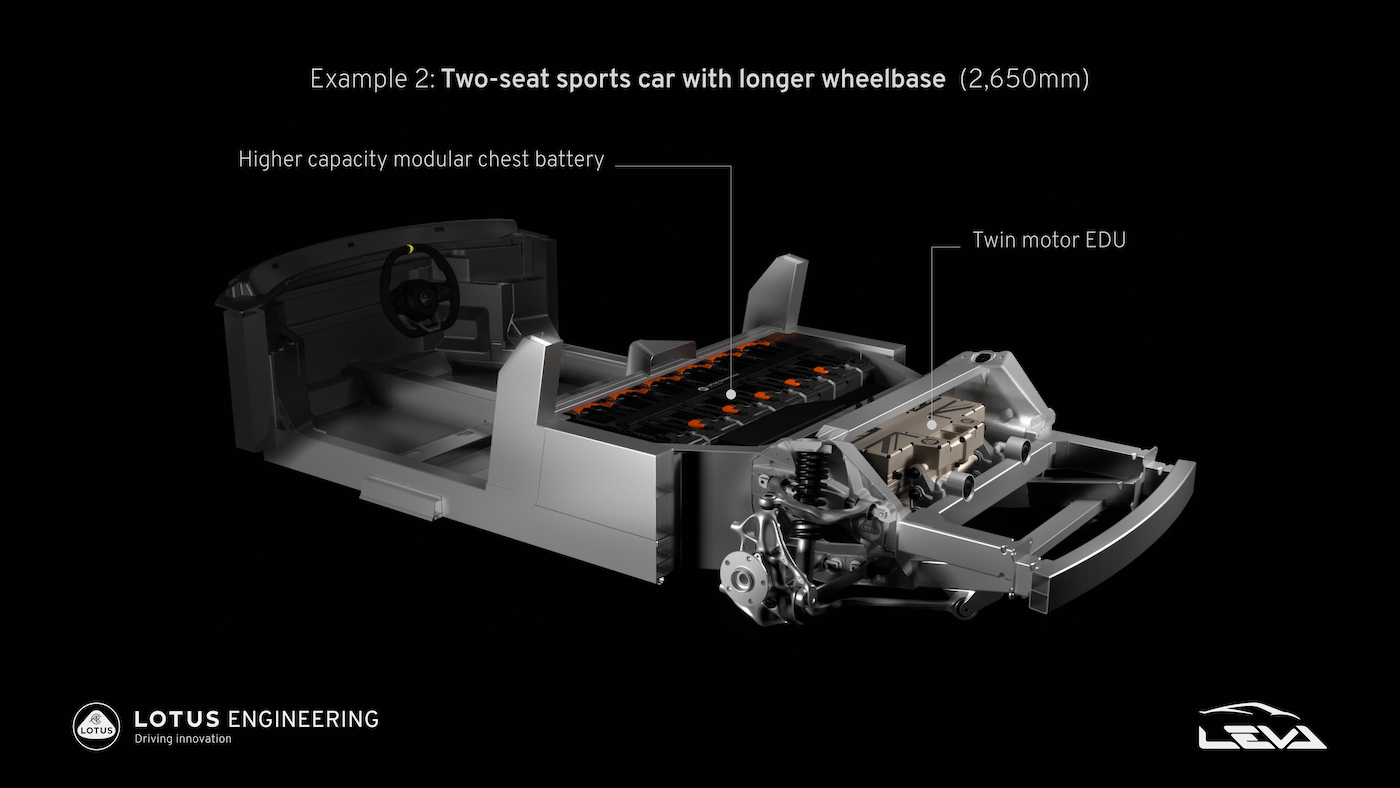

Lotus gives examples of three layouts, each of which features a common lightweight die-cast rear sub-frame with multiple interchangeable components. These layouts are a Project LEVA innovation, and enable a single vehicle architecture to accommodate two different types of battery configurations.

The first configuration, the ‘Chest’ layout, has the battery modules stacked vertically behind the two seats. A chest layout is a mid-mounted power pack, ideal for sports car / hypercar vehicle types where a low overall ride height and low centre of gravity are required – as seen on the Lotus Evija pure electric hypercar.

The second configuration, the ‘Slab’ layout, has the battery modules integrated horizontally below the cabin. This is most suitable for vehicles where a higher ride height and a taller overall profile is required – often referred to as a ‘skateboard power pack’ layout.

| Vehicle Layout | Wheelbase | Battery size / Configuration | Maximum battery power | EDU layout / Max power |

| Two-seater | Minimum of 2,470mm | 8-module / chest | 66.4kWh | Single / 350kW |

| Two-seater | More than 2,650mm | 12-module / chest | 99.6kWh | Twin / 650kW |

| 2+2 | More than 2,650mm | 8-module / slab | 66.4kWh | Single / 350 kW or Twin / 650kW |

The subframe features cylindrical battery cells for high energy density, with the option of a single or twin electronic drive unit (EDU) to support. Cold cure, spot bonding and advanced weld processes mean reduced environmental impact during assembly.

Funding for the project came in part from the Advanced Route to Market Demonstrator programme (ARMD). Richard Moore, executive director of engineering at Lotus Cars commented, “Today’s EVs are heavy in comparison to their ICE equivalents, so the ARMD funding has helped Lotus to innovate earlier in the product cycle and develop a new vehicle architecture that targets lightweight and performance density from conception. Rather than developing a single vehicle, it means Lotus now has the ‘blueprint’ for the next generation of electric sports cars, for future Lotus products and for the Lotus Engineering consultancy to commercialise.”

Project LEVA has been led by Richard Rackham, an engineer and head of vehicle concepts at Lotus, who worked on development of the extruded aluminium Lotus Elise architecture 25 years ago. Rackham commented, “Project LEVA is as revolutionary now as the Elise architecture was in 1996. In true Lotus spirit, significant weight savings have been achieved throughout, with a focus on ultimate performance, efficiency and safety being engineered into the structure from the outset – for example, by utilising the vehicle structure as the battery enclosure, having an integrated EDU, eliminating subframes and optimising the multi-link suspension components.”

On Project LEVA, Lotus has collaborated with supply chain partner Sarginsons Industries and academics from Brunel University London to harness the full ‘light-weighting’ potential of the vehicle architecture.