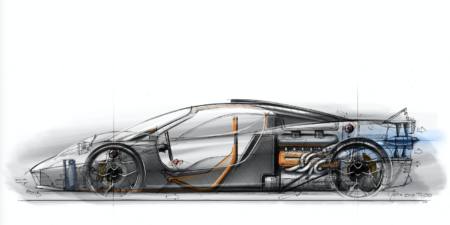

FCA US is exploring an innovative way to poke holes in conventional vehicle engineering. Naturally, weight reduction can be achieved by using less material, but the challenge is determining which components can withstand weight reduction – and by how much – while still satisfying customer expectations for vehicle durability and performance.

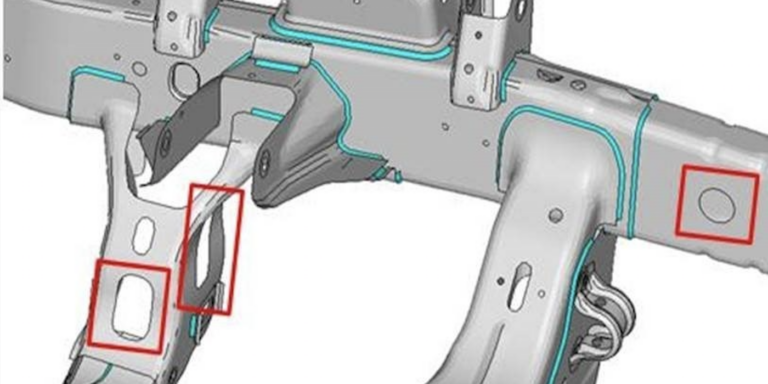

FCA US engineers have developed multiple algorithms to precisely determine the optimal size and shape of “lightening holes”. The algorithms may be applied to any component, and simulations on virtual truck-frame components saw weight savings of 3-5%. With such a tool at their disposal, vehicle development teams can accelerate their work, which benefits customers by reducing the time required to bring new products to market.

“FCA US is committed to designing and producing lighter, more fuel-efficient vehicles that still meet the demands of our customers,” said Phil Jansen, head of product development, FCA – North America. “The all-new 2017 Chrysler Pacifica meets these criteria. Not only is it 250 lbs lighter than the vehicle it replaced, the Pacifica is larger and stiffer. Such progress bodes well for our ongoing investigation of strategic material placement.”