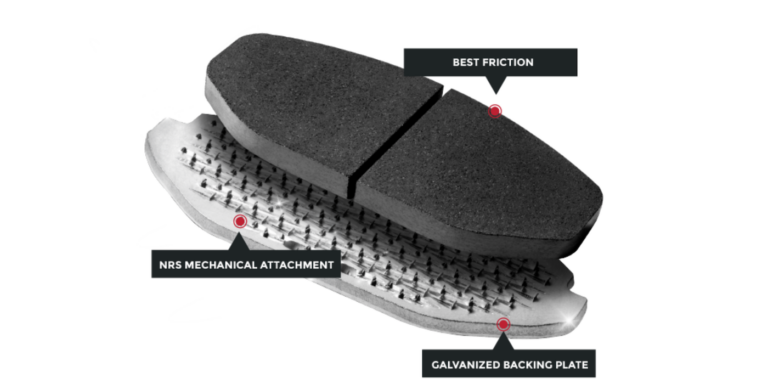

Nucap Industries has launched a new, proprietary line of galvanized brake pads featuring mechanically attached friction on a galvanized steel backing plate. The pads, being sold under the NRS Brakes brand, are galvanized rather than painted and work with all friction composites. The range is aimed at mechanic and end-user communities across North America.

“Mechanically-attached friction on a galvanized steel backing plate is by far the safest, most long-lasting brake pad you can install in a vehicle today,” stated Montu Khokhar, CEO of Nucap Industries. “Galvanized brake pads represent a revolution in brake pad technology, and as a response to a lack of consistency in the aftermarket.”

The NRS brand name refers to Nucap’s mechanical retention system, which enables the steel to be coated prior to pressing friction composites such as ceramics, metallic, or organics via flash molding, positive molding or cold fusion technology. NRS is effective under all these conditions, according to the company.