With air suspension applications growing in popularity for EVs and at the same time, EVs becoming more affordable, car manufacturers are facing new NVH challenges. One example is the demand for a simple and affordable levelling system that would make this premium feature available for smaller vehicle segments. Vibracoustic, an automotive noise, vibration and harshness (NVH) company, has developed a hydro levelling system that it says brings the benefits of ride height adjustability at lower cost to new market segments. The patent-pending hydro levelling system can be tailored to front or rear-axle applications and enables ride height adjustability of lower segment cars, including smaller EVs.

The company has produced a fully operational prototype of the hydro levelling system (integrated into a popular European C-segment vehicle) that delivers 40mm of travel at each wheel, but that travel can be adjusted for each vehicle case. When used as rear-axle application, Vibracoustic says the system can compensate for trunk loading, deliver improved comfort, and maintain ground clearance for fully loaded vehicles, adjust the angle of stall for improved battery cooling of EVs, or provide a more comfortable loading / unloading position. When applied to both the front and rear-axle, it can additionally adjust ground clearance for speed bumps and driveways, or lower the vehicle for high-speed driving to reduce drag and increase range.

Air springs and complex actuators are currently the only established automotive levelling solutions and, while extremely effective, they are typically too complex and costly to fit to non-luxury or smaller vehicles. The hydro levelling system is designed to enable car manufacturers to include single or dual-axle variable ride height systems at significantly lower cost. Vibracoustic says it is already discussing upcoming applications with several car manufacturers, including all-new EV models.

How it works

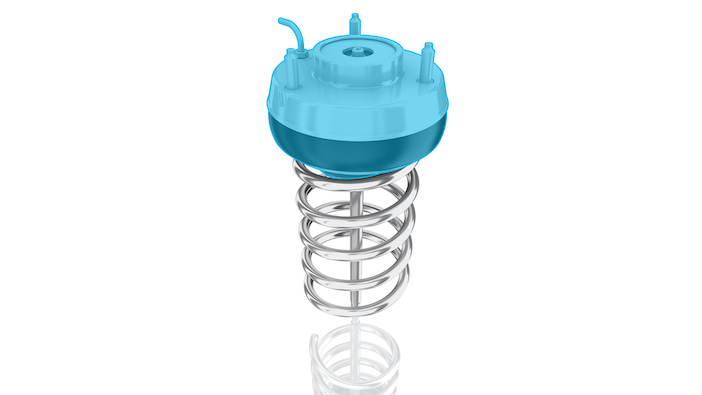

At the core of the hydro levelling system is a hydraulic actuator. The design of the actuator is based on the company’s air spring technology and its knowledge of rubber to metal components. The hydro levelling system is controlled by a dedicated ECU, including software developed by Vibracoustic. It incorporates height sensors and a powerpack (pump, tank, valves). The system offers a levelling speed of 10mm per second in two-corner applications, operating when the vehicle is static.

Prototype testing highlighted that the hydro levelling system in a C-segment vehicle “substantially” improved the ride and comfort metrics of a loaded vehicle. Tested under rough road conditions of different amplitudes and frequencies, Vibracoustic claims the system offered “large comfort improvements” at low frequencies of up to 15 z due to reductions in road-induced excitations.