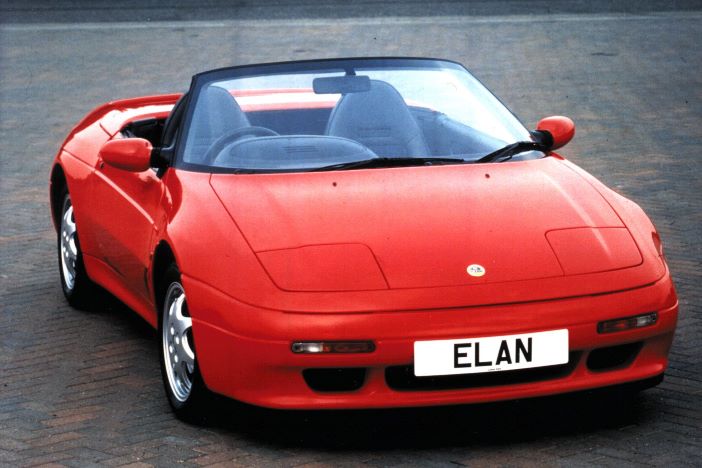

In this column from 2014 John Miles looked back on the dynamics challenge of making the FWD Elan into a true Lotus sports car.

Back in the late 1970s, I bemoaned the fact that rear-wheel drive family cars were getting rarer. Ford come out with the awful FWD Escort, unbelievably claiming it was competition for the Alfasud and Golf in terms of chassis dynamics. For me the ‘eureka moment’ came when the backstreet tuning boys started doing turbo conversions for hot hatches. Yes the engines were often ‘grenades’, but the cars were phenomenally quick and, most importantly, foolproof to drive. Excessive wheel spin acted as a safety valve, not a tail slide. These cars made supercars of the period look poor in comparison, in terms of A to B driving in all weather.

Then I re-joined Lotus when there was much talk of the new Elan and what should it be? What was the point of rear-wheel drive? How much power could a FWD drive car take? Which was more effective, FWD or RWD? At the time, Toyota made both RWD and FWD Corollas of the same weight, same power, and with the same tyres. Wet or dry, circuit or Alpine climb, the FWD car was faster everywhere, and with any driver – and by a big margin, especially in wintery conditions. Lotus might have overlooked the enthusiast’s preference for a car that is a little bit of a challenge to control at the limit, but the cold performance facts said a lot at the time.

Added impetus to go FWD came from the availability of a new Isuzu 160bhp 1.6-litre turbocharged powertrain, which, after 25 years, has proved spectacularly reliable, and shoves the 1,050kg car along extremely well – and it provided a business case for making the car in the first place. Okay, so this was a car with no real competition potential, but instead there was the challenge to make a FWD car without the usual torque-steer issues.

We soon found that the FWD stability theory was correct, and that the biggest disturbing forces in the steering system are top- and end-view driveshaft angles, and especially the hub height offset between tyre centreline and the king pin axis, wherein the outer driveshaft UJs should reside. Different driveshaft angles mean different side-to-side secondary drive shaft couples (moments), which are then exaggerated by hub height offset as the car is hauled forward. Gosh we had fun shifting the engine around on the Toyota Corolla ‘mule’ and watching the unattended steering veer off to the left or right. Yes, all received wisdom was proven, including the desirability for equal-length driveshafts, and that end-view driveshaft angles should run upward to the hub as this generates an outer shaft couple to partially resist the powerful toe-in steer moments as you accelerate.

Even with the Elan’s (by modern standards) moderate output, it proved essential to severely limit the rotation of the powertrain to prevent throttle on/off ‘shunt’, and the resulting long torque arm running rearward into a fixing within the backbone was one of the car’s better mechanical features. In the end, you could slam the throttle on and off in a corner, or straight ahead, with hardly a quiver at the steering wheel.

Until recently, FWD hot hatches were in the same place as we were back in the 1980s. Audi ‘solved’ the critical hub height offset issue with its complicated Dopplegelenk front suspension, whose linkages allowed very low KPI. Unfortunately, the necessity for five ball joints (one very highly loaded) and a poor damper ratio, led to lack of steering feel and durability issues.

Then some bright spark came up with the much simpler way of reducing the hub height offsets, and in turn, more or less eliminated the dreaded torque steer. The end-view angle of a conventional strut fixes the hub height offset; but with a fixed strut, an old-style short king pin can be packaged close up to the brake disc, and within the wheel envelope, also resulting in much lower KPI and offset than with conventional rotating struts. The ‘Revo’ type knuckle, as Ford calls it, enables the recent [2010s – Ed] crop of FWD hot hatches to deliver getting on for 300bhp to the road surface in a controlled manner.

The best FWD limited-slip unit I ever tried was a Torsen all-gear type made by Quaife, a design usually limited on life. Once again, digital control technology seems the way forward. The Ferrari 458 E-diff accounts for much of its highly rated dynamic behaviour. With all the necessary sensors in place, the same opportunities are there with FWD, by precisely controlling torque transfer and wheel spin over the entire speed range without using one-wheel braking, as with the ESC. With systems like the electrohydraulic BorgWarner e-FXD (in production with VW/Audi), traction, and most importantly yaw behaviour, can, at a cost, be beneficially adjusted to taste, without the typical trade-off of excessive understeer.