Projector-based visual systems have been a mainstay of driving simulators since their inception. Even in the future, Cruden, a designer, manufacturer and integrator of open-architecture driving simulators, expects that many simulators will continue to use multi-channel projection systems. With LED projectors now replacing the old-style, lamp-lit models, both image quality and projector longevity are much better than they were a decade ago.

However, the company has also been monitoring advances in direct-view LED panel technology for some time. You’ll have seen these huge screens in city centres, or at airports or sports venues, often being used to display commercials or other media. Such screens are usually viewed at quite a distance and often have distance between the pixels. But with recent advances in terms of pixel pitch, which refers to the closeness of the pixels to one another, the door has opened to their use in driving simulators, too.

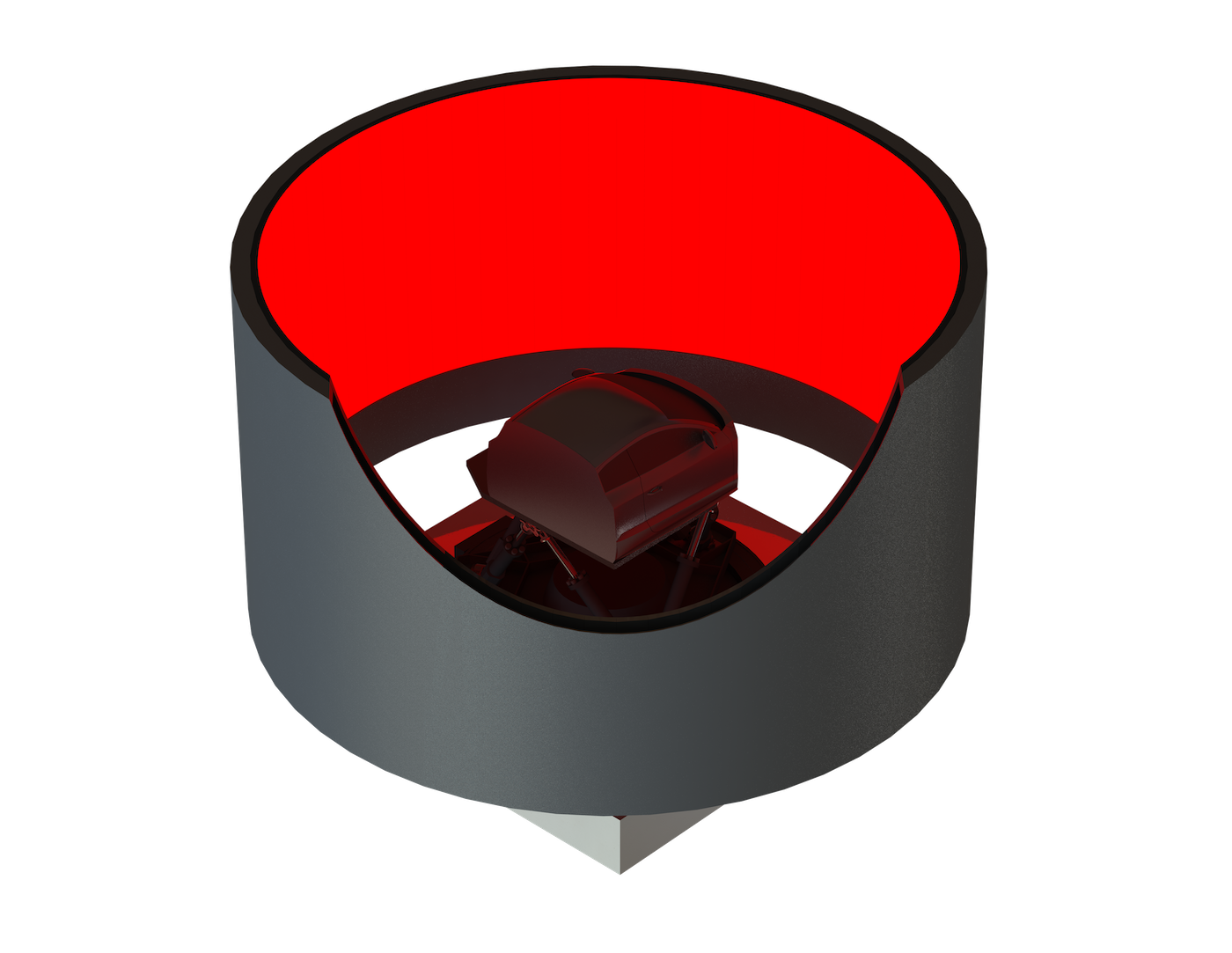

Let’s begin by looking at the current projector technology. In a driving simulator, a projection system is good for creating a large screen at a distance that is far enough away from the driver – typically 3m to 4m – for them to feel like they are looking into the distance. A driver naturally focuses on objects that are in the distance, so it is important for the immersion of the simulator not to have those objects projected close-up, for example on a laptop screen.

However, projectors also have some problems. One is that the light path to the screen must always be free of the envelope of positions created by the moving structure of the vehicle mock-up on the motion system. The need to avoid shadows on the screen can often lead to suboptimal projection layouts. Instead of placing the projectors in the centre of the simulator, in line with the driver’s eyepoint, they are typically moved towards the ceiling.

This shift upwards means that the projectors are closer to the top of the screen than the bottom, so the brightness at the top is correspondingly higher than it is lower down. The same goes for pixel density: the closer the screen is to the projector, the smaller the pixels are on the screen. Further down and further away, the larger pixels compromise the image uniformity that you would be achieved, were the projector in the ideal location. The pixels, as well as the projected images, are no longer square, and the trapezoidal blend zones are wider at the bottom of the screen than at the top, which leads to ‘spilling’ of pixels and a reduction in system resolution and brightness.

This brings us to the newer direct-view LED panel solutions, the pixel-pitch of which has reduced in recent years from a minimum of around 2.5mm to as little as 0.9 to 1.5mm, which matches the system resolution requirements for the visual system of an immersive driving simulator. Truly curved LED panels still don’t go down that far, but curved screens suitable for driving simulation can be built from planar LED segments, which come in sections ranging from 8cm x 11cm, to 60cm x 35cm, depending on the solution and vendor. Cylinder, U-form or any other screen shape or aspect ratio can be created, simply by stacking the panels horizontally and vertically in the right combination.

The resulting LED panel image will have advantages over that of a projector image, for several reasons. One is the absence of the task of blending adjacent images in order to create a single image from multiple projectors. Also, the geometric correction (warping) of the images is much more straightforward, because with LED panels, the location of each pixel is known and can therefore be addressed directly from the image generator that renders the images. No pixels or render performance is spilled, as all the rendered pixels will be used to show one synchronous image distributed over adjacent panels.

Removing the blend zones brings further advantages in low-light conditions. Typically, a blend zone is visible on a projection screen displaying night-time scenarios because the projector is not capable of showing true black. The possibility of showing true black with LED panels results in a huge contrast increase compared with images of a projection system with the same luminance.

The human eye is very good at compensating for a lack of brightness, but can never compensate for lack of contrast. High contrast is therefore a very important aspect in all visual systems, including those in simulation. Here, the LED wall solution is a big improvement because it offers virtually unlimited contrast.

The additional contrast also helps create a better-defined image. The driver or test subject in a simulator can recognise subtle details in the image that might otherwise fall away in the very small differences of lower-contrast projection solutions: a more recognisable bump in the road or clearer road signs in the distance, for example. That, in turn, leads again to better immersion, as does an LED visual system’s ability to show a much better-defined image.

Reduced maintenance downtime is a further advantage of an LED panel solution. Since there is no projector attachment to the ceiling, no post-maintenance recalibration of the warping and blending is required after reattachment. Instead, the solid-state LED panels not only have fewer things to go wrong, but when something does, each individual segment can easily be replaced from the front side. The new unit can then be matched with the other segments in the LED visual system, and a consistent image will be up and running again straight away.

The system’s longevity is good, too. The degradation in the brightness of the LED visuals in a driving simulator application has been calculated to be negligible.

With such promising fundamentals in place, Cruden has been working with LED panel manufacturers and signal processing developers to fully harness the potential of this technology for driving simulators. The low latency and 120fps frame rate requirements are aspects that have been addressed. This refresh rate isn’t critical for showing a big-screen commercial at an airport, and neither is a very low latency, but both factors are essential for driving simulation, so the developers have worked to ensure that this can be implemented.

Effects such as the smearing or ghosting that you sometimes see on a television – the streak of colour that can get left behind a fast-moving object – also need to be eliminated because of the simulator’s reliance on fast-panning visuals. To avoid unwanted ‘artefacts’, you need a careful combination of the right LED panels plus a good-quality driver and signal processing. Optimised image processing can reduce the unwanted phenomena and enable the high frame rates and processing tricks that will improve image quality, without adding latency or other negative effects to the immersive experience.

The LED panels that are used in off-board simulator visual systems are currently not suited for use on-board simulators – screens mounted directly on the simulator motion system – as the panel structures are not designed for dynamic applications, and also the pixel pitch isn’t yet high enough for their use so close to the driver. Instead, Cruden is now busy replacing its custom-developed, LED-backlit LCD displays that are used on-board its motion platforms, with OLED technology that is also used in televisions. These OLED panels have the further advantage that they can be curved to wrap around the driver. If the space in your facility is limited or the budget isn’t available for a large off-board projection or LED panel type visual system, then onboard OLED visuals are a good alternative.