The shortlist for the 2023 Vehicle Dynamics International Awards showed the depth of engineering, innovation, technology and teamwork taking place in the sector. Take a look at the finalists and the ultimate winners, as decided by our international judging panel.

The judging panel:

- Choi Joo-sik, Autocar Korea

- Robert Bielecki, Oponeo, Poland

- Christophe Congrega, L’Automobile Magazine, France

- Brian Cowan, freelance, New Zealand

- Carl Cunanan, C!, Philippines

- Padraic Deane, managing editor, Automotive Publications, Ireland

- Tarcisio Dias de Araujo, Mecânica Online, Brazil

- Jim Kenzie, Toronto Star, Canada

- Nikos Kounitis, 4Wheels, Auto Bild Hellas, Greece

- Nicol Louw, Car South Africa

- Marco Marelli, freelance, Italy

- Frank Markus, Motor Trend, USA

- Marc Noordeloos, freelance, USA

- Sergio Oliveira de Melo, El Informador, Mexico

- Phil Morse, Energy Balance, USA

- Tomaz Porekar, Avto Magazin, Slovenia

- Alvaro Sauras Alonso, Autofacil and CAR&Tecno, Spain

- Mohamad Sheta, Al-Masry Al-Youm Newspaper, Auto Arabia, Middle East Auto News Agency

- Gábor Szécsényi, Az Autó and Retro Mobil, Hungary

- Oleg Vasilevsky, Auto Bild, Ukraine

- Adam Gavine, Vehicle Dynamics International, UK

- Hormazd Sorabjee, Autocar India

- Jürgen Zöllter, freelance, Germany

If you would like to see your favourite dynamics team, technology or initiative considered for the 2024 Vehicle Dynamics International Awards shortlist, send details to adam.gavine@markallengroup.com

Car of the Year

Car of the Year: Among the models launched in 2023, which new vehicles impressed the panel most with their dynamics setups?

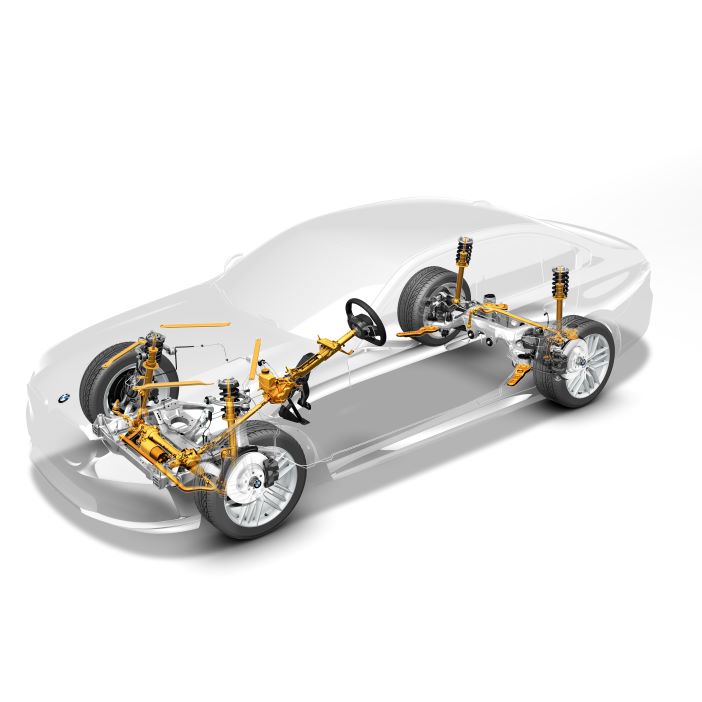

WINNER: BMW 5 Series saloon

The BMW 5 Series has been a benchmark in the executive category since its launch five decades ago, and the eighth-generation model takes its dynamics a step further. Both the aluminium double-wishbone front axle and the aluminium five-link rear axle of the saloon have undergone extensive development as part of the work of ensuring the 5 Series’ legacy of blending luxury and sportiness continues.

As with each generation of the 5, the new G60 model has grown a little, being 97mm longer (now 5,060mm), 32 mm wider (now 1,900mm) and 36mm taller (now 1,515mm), with the wheelbase extended by 20mm, to 2,995mm, the longest in the upper mid-range segment. BMW claims a near 50:50 axle load distribution ratio.

The front axle support has received an elastic steering gear mount to optimise the acoustic properties, with the all-wheel-drive variants featuring an aluminium stiffening plate under the front axle support, for optimised rigidity.

An interesting new feature of the saloon is its directly controlled wheel-slip limitation function, which helps maximise agility and control in demanding driving situations. The traction control is integrated into the engine control unit, which eliminates the long signal paths to the control unit of the DSC (Dynamic Stability Control). While the raw figure may be small, this setup means that the control interventions take place up to 10-times faster than in the previous-generation 5 Series.

The new 5 is also equipped with the latest electromechanical power steering as standard. The standard sport steering now includes a direct and steering angle-dependent ratio, with its range of functions including Servotronic speed-related power assistance.

The advanced Integral Active Steering option is also available for the saloon as part of the Adaptive Suspension Professional package with electronically controlled dampers. Depending on vehicle speed, the rear wheels are turned either against the front wheels or in the same direction by up to 2.5°. At low speeds this aids manoeuvring in and out of parking spaces, while the turning circle is reduced by more than 0.6 metres, to 11.7 metres.

The M sport suspension option includes a firmer tuning setting of the springs, dampers and anti-roll bars, combined with a lowering of the vehicle by 8mm.

The latest 5 Series is available with several powertrain variants, from ICE to hybrid and electric, which means a broad range of vehicle weights, and more requirements for tuning chassis components and control systems, making BMW’s work even more impressive.

Runners up:

Ferrari Purosangue

The scoring was very close this year, with not much to separate the 5 Series from the Ferrari Purosangue. While a very different driving proposition, the Purosangue has some similarity, being billed as a four-door, four-seater car. However, the Purosangue has a mid-front-mounted engine, with the eight-speed gearbox at the rear to create a balanced and sporty transaxle layout, and the Power Transfer Unit (PTU) coupled in front of the engine to provide four-wheel-drive. The result is a 49:51 weight distribution.

The Purosangue boasts an all-new chassis. The lower structure is made from high-strength aluminium alloy which, together with the structural elements of the upper body, makes up a spaceframe chassis comprised of closed-section extrusions connected by castings into which load-bearing aluminium sheet elements are integrated.

The chassis is thus lighter than that of Ferrari’s previous four-seaters – from the 1952 250 GT/E to the 2016 GTC4 Lusso – despite being larger, with a focus on torsional rigidity and beam stiffness to achieve the NVH characteristics required of a luxury car.

The Purosangue debuts an active suspension technology enabled by Multimatic’s True Active Spool Valve (TASV) System, an architecture that combines electric motor actuation with a spool-valve hydraulic damper in one integrated system. According to Ferrari the TASV 48V electric motor applies force in the direction of the damper’s stroke, ensuring that body and wheels can be better controlled and at higher frequencies than traditional adaptive or semi-active systems.

The car is also equipped with a new front semi-virtual, high wishbone suspension, with the lower wishbone having two attachment points on the hub carrier. The virtual lower kingpin attachment point created by the two arms is very close to the wheel centre, reducing the scrub radius.

Hyundai Ioniq 5 N

The Ioniq 5 N is Hyundai N brand’s first high-performance, all-electric model. The car is based on the Ioniq 5 E-GMP (Electric Global Modular Platform), with N’s motorsport-bred technologies and expertise from electrified ‘Rolling Labs’ (e.g., RM20e, RN22e and N Vision 74) added to maximise the EV’s high-performance capabilities and ensure it meets N’s three performance pillars: ‘Corner Rascal,’ ‘Racetrack Capability’ and ‘Everyday Sportscar’.

The model may sound a little specialist, and perhaps rather playful, but its dynamics technologies are serious and Hyundai expects they will bring benefits into future models.

Awards juror Jürgen Zöllter said of the car: “The Ioniq 5 N combines a highly advanced battery-electric platform with state-of-the- art, fun-to-drive handling features in a future- oriented way. This combination is unique in this EV segment.”

2024 Ford Mustang

The all-new, seventh-generation Ford Mustang is billed as being the most exhilarating and visceral version yet. Quicker steering ratios and minimal compliance from steering wheel to tyre have been introduced to enhance the cornering dynamics, which are combined with increased engine power.

The car is based on a unitised steel chassis with fully independent front/rear suspension and perimeter subframe, and a tower-to-tower brace in the Performance Package. The front suspension features a double-ball-joint MacPherson strut with stabiliser bar and aluminium control arms. At the rear is an integral-link independent suspension with coil springs and stabiliser bar.

Even better, the optional Performance Pack adds a front tower brace, Torsen LSD, optional MagneRide active suspension, wider rear wheels and tyres, 390mm front and 355mm rear Brembo brakes, and an electronic drift brake.

Dynamics Team of the Year

From developing dynamics innovations to applying them to production vehicles, this category recognises the work of OEM and consultancy dynamics teams around the world

WINNER: Porsche

The dynamics team at Porsche earned some rest after the launch of the new 911 GT3 RS, but they have had several more exciting projects to complete over the past year.

The new Panamera is equipped with a semi-active chassis with two-valve shock absorbers as standard, while a new option is a high-end chassis with active damper control and a wide range of additional functions, which enhances ride comfort and agility.

Porsche has also overhauled the third generation of the Cayenne with comprehensive changes to the powertrain, chassis, design and equipment. This has further extended not only on-road and off-road performance, but also ride comfort. Porsche now equips the Cayenne at the factory with a steel spring suspension including Porsche Active Suspension Management (PASM). New shock absorbers with two-valve technology and thus separate rebound and compression stages allow optimised performance in all driving situations.

Continuing the off-road theme, the 911 Dakar features a retuned chassis and a lift system that enables the car’s ground clearance and ramp angle to rival those of conventional SUVs, while retaining the feel of a regular 911.

Porsche is also celebrating the 60th anniversary of the 911 (marked with a special edition 911 S/T) and the team is busy working on new projects including a 911 refresh with new models, a second-generation Macan, next-generation 718s, and several electric variants.

Runners up:

Fatigue4Light

Fatigue4Light is an EU-funded initiative that aims to develop chassis technologies that can reduce the weight of EVs and reduce sprung mass to enhance safety. The project is working on applying new materials tailored to chassis requirements, such as advanced high-strength steels, high-strength aluminium alloys, and hybrid metal-fibre reinforced polymers. The project deliverables will enhance new material selection and significantly shorten lead time between material development and the design of a new chassis part. There are currently 13 partners in the project.

VI-grade, Chassis Autonomy & CAE Value

Three providers of automotive simulation technology have joined forces with the aim of disrupting and improving how chassis components for autonomous vehicles are designed, tested and validated. The companies are VI-grade, a simulation specialist; Chassis Autonomy, a start-up that designs and manufactures fail-operational actuation systems for highly automated and fully autonomous vehicles; and CAE Value, a simulation company.

The three companies are collaborating to advance the development of autonomous vehicles, creating new advantages for the autonomous vehicle market as well as for each of the respective companies.

Toyota

Toyota Motor Corporation (TMC) also has a big celebration this year, having reached a cumulative global production total of 300 million cars since the company started 88 years ago.

The Corolla accounts for 53.399 million cars of that output, and the new model is sure to continue the success, being based on the Toyota New Global Architecture (TNGA) platform, with a low centre of gravity and reduced NVH.

The team have also updated another classic, with the all-new Land Cruiser. The model carries on the classic, robust body-on-frame construction, and is based on Toyota’s GA-F platform. The new frame is 50% more rigid than the previous version, and the combined body and frame is 30% more rigid. Basic suspension performance has also been enhanced, and a disconnecting front anti-roll bar added.

A few Japan market models have also been enhanced, such as the all-new Alphard, Vellfire and Crown Sedan – the latter gaining improved torsional rigidity and ride comfort.

As VDI Awards judge Marc Noordeloos says: “Toyota has become a dynamics powerhouse.”

Innovation of the Year

This category recognises good design and technology in the vehicle itself

WINNER: Wheel hub with integrated brake

Continental has partnered with DeepDrive (a developer of electric motors) to develop core technologies for EVs. The first step in the partnership is the joint development of a combined unit comprising drive and brake components that can be mounted directly on a vehicle wheel.

The companies hope to capitalise on the potential to place all chassis functions, including the drive, directly on the wheel in EVs. In order to best meet the particular requirements of EVs, such as maximising driving range while minimising installation space and introducing modularity, optimisation at the vehicle level is necessary.

The optimal coordination of brake and drive systems is a key factor, with the integration of both elements in one unit enabling a high level of efficiency in the drive and when braking. Having integrated components also reduces complexity through modularisation and facilitates the manufacturing process.

DeepDrive’s dual-rotor, radial-flux motor can be installed as a central drive unit or as a wheel hub drive in series production vehicles. The partners will focus on developing an efficient, compact wheel hub drive optimised with a view to cost-effective production, with Continental contributing brake components and its expertise in industrialising products through to series development.

The first stage of the collaboration will see a hydraulic brake integrated into the drive-brake unit. In the second step, the companies plan to integrate dry braking systems without hydraulic components into DeepDrive’s wheel-hub drive.

The combination of drive and brake in one unit is also the first step towards enabling the design of a compact corner module with integrated chassis components, such as air suspension systems from Continental, mounted directly on the wheel.

Runners up:

Dash-CAE TR01 monocoque

Dash-CAE’s TR01 is a carbon monocoque chassis for road or race cars that is claimed to deliver a “step change” in price to performance ratio, enabling broader use of the material in performance automotive and motorsport. The headline figures are a stiffness of 35,000Nm/Deg, a weight of 50kg, and a price below £30,000 (US$38,000) – quite a saving in terms of time and cost for a production carbon monocoque.

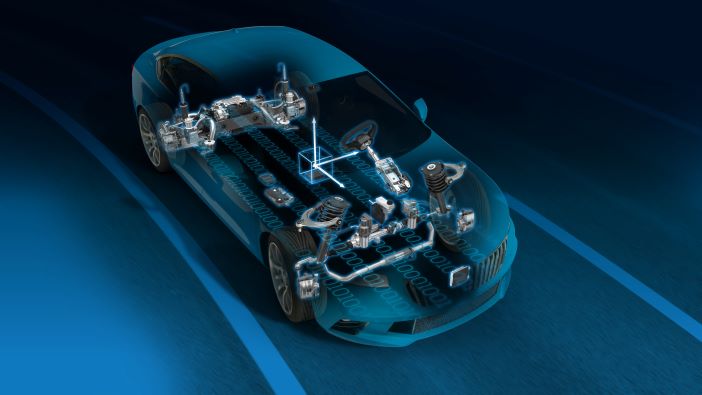

cubiX dynamics software

Achieving harmony between the longitudinal, lateral and vertical dynamics is important for creating a pleasant and comfortable driving experience, a balance that is even more important for AVs, in which the driver is less focused on driving activity and more on comfort. The newly developed cubiX software – ZF’s first pure software product – controls all chassis systems to achieve a harmonious blend of smooth acceleration and braking, precise steering, and balanced damping. Software such as cubiX is a move towards the software-defined vehicle.

cubiX has been installed in the Lotus Eletre EV, in which it controls all chassis functions such as brakes, front and rear axle steering, active roll stabilisers, as well as the electric drive.

Applied in-wheel propulsion system

Elaphe and McLaren Applied are collaborating to create an in-wheel propulsion system for a new vehicle segment of highly efficient and hyper-responsive EVs. The system couples McLaren Applied’s inverter technology with Elaphe’s direct-drive in-wheel motors and control software, and multiple-wheel drive controls and vehicle controls. The partners say the combined system offers long-range cruising efficiency and vehicle controllability, with a torque response claimed to be five-times faster than that of existing systems.

The technologies will be combined in an in-wheel propulsion system that couples McLaren Applied’s inverters with Elaphe’s direct-drive in-wheel motors and vehicle controls. Together, say the companies, the in-wheel system will enable ‘significant’ space and weight savings for OEMs, as well as reduced vehicle energy consumption.

MK 120 ESC brake system

Continental was in the running again with its MK 120 ESC, the latest generation of its conventional electronic brake systems, which it says is efficient, offers cyber security features and over-the-air (OTA) functionality, and can be easily installed in a vehicle. Changan is the first OEM to put MK 120 ESC into series production, equipping its Oshan X5 Plus and Uni-T models with the brake system. A European OEM is due to follow.

Development Tool of the Year

Developing a great dynamic setup requires great tools. This category rewards the latest tools that help vehicle dynamics engineers evaluate their designs and setups to achieve automotive excellence

WINNER: VI-grade DiM300 driving simulator

VI-grade’s new DiM300 Driving Simulator introduces a host of cutting-edge features, including an extended operating range and higher tripod velocity, for higher levels of realism and versatility.

The DiM300 is an extended version of its DiM Dynamic Driving Simulator Technology, featuring extended linear actuators for increased travel of the tripod and longer steady-state accelerations. This extended operating range and higher tripod velocity enables the simulator to perform large planar displacements with virtually no motion cueing, providing engineers with greater realism and versatility.

Vehicle dynamics applications include chassis tuning, tyre development, driver training, and control system design.

The technology has already found its first customer, at Honda Japan, with Progress Technologies Group, a Japanese engineering service provider, to follow.

This win follows VI-grade earning the Development Tool of the Year prize in 2018 for the DiM250 simulator, a model used by clients including Honda R&D Europe and Mercedes-AMG.

Runners up:

SPMM Plus

The SPMM Plus suspension parameter measurement machine from AB Dynamics is claimed to be the world’s most accurate K&C test machine, used to measure and analyse suspension movement whilst subjecting it to

a faithful replication of on-road vehicle behaviour through a unique moving centre table architecture.

The new ‘Plus’ version of the machine provides Moment of Inertia (MoI) and Centre of Gravity (CoG) measurements to generate all the chassis-based data required to create and correlate virtual vehicle models. It also features a high-speed digital control system, high-velocity actuators, increased vertical stroke capacity, and table extensions to accommodate a wider range of vehicles.

Simulation 2022.3

Automotive software company, Altair, has released updates to its simulation package, under the name Simulation 2022.3. These updates focus on cloud collaboration and computing, efficient end-to-end simulation workflows, and improved design creation with AI-powered simulation.

The Simulation 2022.3 updates allow users to eliminate data silos, IT constraints and access barriers. In addition, new seamless digital thread workflows connecting Altair One and Altair HyperWorks – Altair’s design and simulation platform – will enable users to preview and modify models and track data, access online libraries, and more. These functions are available within a single sign-on ecosystem that can be accessed from any location.

Test Facility of the Year

This category recognises the most impressive new developments and investments at proving grounds and test tracks, as well as facilities offering the use of dynamics test equipment

WINNER: BMW Group FMD

BMW Group has opened a new €300 million (US$326 million) test site in Sokolov, Czechia, created for fully automated development and test drives. As the first development location of its kind in central Europe, the Future Mobility Development Center (FMDC) will play a key role in the company’s future mobility development.

The 600-hectare facility enables all possible driving conditions to be undertaken, including countryside, freeway, and automated parking (up to level 4), to supplement virtual driving simulation. With the test vehicles being automated, test programmes can continue through the night without drivers becoming tired.

The terrain surrounding the centre, a former mining region, also offers challenging real-world driving conditions. Even better, the FMDC and its charging infrastructure are supplied with 100% green electricity from renewable energy sources, while the water management system systematically collects rainwater and uses it for track irrigation.

Runners up:

DRI K&C test facility

DRI’s new purpose-built K&C test facility in California is the only independent site in North America to provide the full suite of Kinematics & Compliance (K&C) tests and Centre of Gravity (CoG) and Moment of Inertia (MoI) measurements. The facilities enable vehicle manufacturers to accurately measure and evaluate a vehicle’s suspension system during development. At the centre of the operation is what DRI says is the world’s most accurate K&C test machine, the SPMM, manufactured by AB Dynamics.

As well as providing industry-standard K&C services, DRI uses the facility to develop bespoke tests to meet customers’ specific research and development requirements. It is also equipped with a highly accurate 3D Coordinate Measuring Machine that enables a vehicle suspension to be accurately modelled.

Horiba Mira Simulator Centre

Horiba Mira has opened a Driving Simulator Centre at its UK head office, with a key feature being its latest-generation driver-in-the-loop simulator technology. The company has invested more than £4 million (US$4.88 million) in the facility, designed to enable automotive OEMs, start-up vehicle manufacturers and tier one suppliers to develop vehicles that meet their target attributes.

At the heart of the centre is the UK’s first DiM250 Dynamic Simulator from VI-grade. Horiba Mira claims that, at full reduction, one vehicle model developed using the DiM250 simulator could avoid a maximum potential of 14,000 tonnes of carbon dioxide equivalent (CO2e). Customers using the centre will also have

access to its VI-grade Compact simulator.

The virtual development tools can be used for many automotive applications such as the driven attributes of vehicle dynamics, NVH and drivability, as well as holistic engineering across ADAS, HMI and x-in-the-loop (XiL) applications.

Smithers Winter Test Center

The Smithers Winter Test Center in Michigan, USA is celebrating its 50th anniversary, which coincides with the company adding ISO 19447 testing to its scope of accreditation. ISO 19447 outlines a method for measuring the relative ice grip performance of passenger car tyres.

ISO 19447 testing is carried out on a flat, polished ice surface that must be prepped at least an hour before a test. The ambient temperature must be between -15°C and 4°C, with the ice temperature measuring between -15°C and -5°C. Following surface preparation, nine test runs are conducted three times, on separate days and surfaces. The highest and lowest scores of each nine-run test sequence are deleted and the remaining data is used to calculate ice grip.

There is growing demand for ISO 19447 testing, but few companies offer the service, mainly because it requires a prepared surface and a fairly extreme winter environment.

Congratulations top all the 2023 awards winners. If you would like to see your favourite dynamics team, technology or initiative considered for the 2024 Vehicle Dynamics International Awards shortlist, send details to adam.gavine@markallengroup.com