There have been impressive developments in vehicle dynamics engineering, innovation, technology and talent, as reflected in the fantastic shortlist for this year’s awards. The quality of the 25 contenders made for tough evaluation by the international judging panel, but five worthy victors emerged. Here are the winners of the 2021 Vehicle Dynamics International Awards…

Car of the Year

There was a performance theme to this year’s finalists, with power spanning 241hp to 577hp. We all know power is far from being the most important aspect of a good car though, so which vehicle impressed the panel most with its dynamics setup?

Winner: BMW M3/M4 Competition M xDrive

The M3 Sedan and M4 Coupé were impressive, and even more so in the Competition specification – but the new M xDrive all-wheel-drive variant gives it even greater dynamic prowess.

The M xDrive all-wheel-drive system splits the power from the 375kW/510hp straight-six engine between the front and rear wheels to enhance agility, directional stability, traction, acceleration and track dynamics. The system uses an electronically controlled multi-plate clutch in the transfer case for smoothly adjustable, fully variable distribution of drive torque between the front and rear wheels. Many of these cars will be driven hard, so the clutch oil supply has been optimised to keep the variable power mechanism performing effectively, even on track.

The power transfer between the front and rear differentials is handled by driveshafts engineered specifically for the M xDrive models, with the bespoke output shafts having a rear-biased setup. The M xDrive-specific control unit enables fully variable distribution of drive torque between the rear wheels and limits wheel-slip. The systems can also compensate for any differences in rotational speed between the front and rear wheels quickly, without having to involve the central DSC management. Did someone say drift?

This setup ensures the power is applied efficiently and effectively, but it could prove a little too much for some drivers, so it is complemented by integrated M-specific traction control and Dynamic Stability Control (DSC) systems to flatter drivers and help keep them safe.

The AWD technology is further complemented by a double-joint spring strut front axle which has been redesigned for the M xDrive models, with specially adapted front-axle geometry and an individually tuned steering ratio so drivers get that special ‘M’ feel through their hands.

If BMW’s dynamics team are currently working on a GTS or CSL model, we could well see the M3/M4 return to the shortlist next year.

What the judges said:

“It’s the ultimate driving machine to crown the ICE-era before it disappears” – Jürgen Zöllter, freelance, Germany

“Feeling that you’re “mastering the beast” while being safe is exciting and a lot of fun” – Gábor Szécsényi, Az Autó and Retro Mobil, Hungary

“High performance within everyone’s reach” – Marco Marelli, freelance, Italy

Special mention: Toyota GR Yaris

We don’t usually give the second-ranked entry so much coverage, but the M3/M4 Competition M xDrive was neck and neck with the Toyota GR Yaris right until the final vote. There may be a power gulf between the two cars – 577hp v 257hp, but in dynamics terms the judging panel clearly considers them virtual equals.

The GR Yaris is a WRC homologation model, developed together with Tommi Mäkinen Racing from the ground up, to be worthy to be sold in Toyota Gazoo Racing’s (GR) sports car lineup. This diminutive hatch will please all keen drivers, with a depth of engineering that includes a highly rigid body tuned for refined balance, and a unique architecture which combines Toyota’s new GA-B platform (which debuted on the new generation Yaris hatchback) and a rear section adapted from the GA-C platform used for the Corolla and C-HR models.

Weight in the upper body has been reduced by 24kg through the use of aluminium (around 10% overall) for the hood (bonnet), tailgate and door panels (note the GR has only three doors), with the roof panel made of C-SMC (carbon sheet moulding compound), a forged (rather than woven) carbon material – a first for a Toyota model, which saves 3.5kg compared to a steel roof and helps lower the car’s centre of gravity. The result in a kerb weight of 1,280kg. Indeed the only exterior parts unchanged from the Yaris base vehicle are the headlights, door mirrors, rear light clusters and the shark fin antenna on the roof.

The desired level of rigidity was achieved by using more weld points, particularly in areas where they can strengthen joints. There are 4,175 in total, 259 more than on the Yaris hatchback. Further gains are made through extensive use of ball joints on the lower side, more rigid bearings and structural adhesives. The joint structure at the rear features a strainer that gives support at 45° from the shock absorber inputs to suppress toppling of the rear wheel housing to give extra torsional rigidity.

28mm) with four-pot aluminium monoblock

calipers (front) and ventilated grooved discs (297 x 18mm) with two-

pot aluminium monoblock calipers (rear)

The team specified a MacPherson strut suspension at the front, with an exclusive, highly rigid front knuckle and a reinforcing patch added to the front lower arm. The rear design uses trailing double wishbones, in place of the torsion beam arrangement of the standard Yaris. The GR-Four sports 4WD setup – the first original sports AWD system Toyota has created in 20 years – uses a front and rear variable driving-force system with a multi-plate clutch (and two Torsen LSDs with the optional Circuit Pack). Freedom of driving force distribution between the front and rear wheels has been increased, making possible the delicate control needed to handle rough road surface conditions at high speed.

The 1.6-litre in-line direct-injection turbo engine is a newly developed compact and lightweight unit, and at 257hp has world’s highest maximum output for a three-cylinder engine – good for 200.8bhp per tonne in the GR Yaris. This TNGA engine offers high-speed combustion, by increasing engine revolutions through the use of lightweight moving parts, and by optimising the turbocharger and other elements of the air intake and exhaust system. The engine is mated to a six-speed iMT (Intelligent Manual Transmission).

The result should be good, as the setup was refined following feedback from professional rally drivers, and indeed Akio Toyoda himself, in his role as a Toyota Master Driver.

A rally driver’s experience with the GR Yaris

Toyota Gazoo Racing World Rally Team driver Kris Meeke was closely involved in GR Yaris prototype testing. “The car is very, very stable and the stiffer suspension gives you a good feeling as you turn into a corner. In a pure performance car, the details need to be exact, because in rallying and racing it’s the details that make the difference,” he says of the GR Yaris.

“Having a car like this, small and lightweight with its own, unique platform, it’s obvious everything has been optimised for ultimate road handling, and you can certainly feel that when you drive it. Having independent suspension at each corner maximises the traction and the forward motion, which what is what a performance car is all about. Coming from a rally background, this car can adapt to all conditions.”

His co-driver, Jari-Matti Latvala adds, “It’s about the closest you will find to a World Rally Car on the street today”.

The rankings:

1: M3/M4 Competition M xDrive

2: Toyota GR Yaris

3: Audi RS3

4: Mercedes-AMG SL

5: Mk8 VW Golf GTI

What the judges said about the GR Yaris:

“A real road rally car! The ferocious engine, the virile gearbox and suspension, and the exciting chassis and transmission with the possibility to oversteer on demand is the perfect combination to have a maximum fun on twisty roads” – Christophe Congrega

“The power of driving pleasure in a small size” – Marco Marelli

“German cars drive great. So balanced, so connected. All the German finalists on this list drive beyond great. Each could be the centrepiece of a master class on vehicle dynamics. But for the pure heel-and-toe fun of it, who could possibly resist Toyota’s little GR Yaris hot hatch? Be honest. The only thing I have against it is its 2,800 lb kerb weight. I assume that must drop to under 2,000 lb after the lead ballasts are removed, right?” – Phil Morse, Energy Balance

“In an automotive world full of ever-advancing technology, Toyota brought back simple, focused and fun-to-drive values with the GT86 in 2012. The hugely entertaining GR Yaris builds on that philosophy without diluting the minimalist experience—impressive given the small hatchback carries both all-wheel drive and a turbocharger” – Marc Noordeloos

Dynamics Team of the Year

From developing dynamics innovations to applying them to production vehicles, this category recognises the work of dynamics teams at OEMs and consultancies around the world.

Winner: Lotus Engineering

The dynamics specialists at Lotus Engineering have had a hectic year, developing a range of vehicle architectures, including the Extreme platform, due to be launched this year with the Evija hypercar; the Evolution platform, the first global automotive architecture from Lotus, which will be the basis for an all-new range of lifestyle vehicles; and E-Sports, an electric sports car architecture that will be used for new products from Lotus and Alpine and which is also commercially available to other OEMs.

The team has also developed the Elemental architecture, a platform for sports cars, which will launch with the all-new 1,405kg Lotus Emira. Flexible, lightweight and featuring a lightweight bonded aluminium chassis technology pioneered by Lotus, this sports car platform is what the consultancy calls “a massive step-change technically”.

Lotus’s dynamics experts have also been working on an innovative lightweight chassis technology that will be integrated into an architecture for Lotus’s forthcoming Type 135 electric sports car, scheduled for launch in 2026. The structure has been developed through Project LEVA (Lightweight Electric Vehicle Architecture), Lotus’s research programme to accelerate the development of all-new lightweight structures for next-generation battery electric vehicles.

The die-cast rear subframe of the Type 135 is a claimed 37% lighter than even that of the Lotus Emira V6. Such an advance has given Lotus the confidence to promote the architecture as the ‘blueprint’ for the next generation of electric sports cars. The vehicle architecture is versatile, being adaptable to provide a platform for a range of electric vehicle types with variable layouts, wheelbase lengths, battery sizes and configurations. The vehicle structure doubles as the battery enclosure, with an integrated EDU, eliminating subframes and optimising the multi-link suspension components.

This quite remarkable depth and breadth of vehicle architecture innovation has earned Lotus Engineering the well-earned title of Dynamics Team of the Year.

Receiving the award, Mark Edwards, executive director responsible for Lotus Engineering, commented, “This award is a huge honour which recognises the exceptional year that our consultancy has had. It’s a fitting tribute to everyone involved, and I know it give them renewed focus for 2022, which is set to be another pivotal year in the ongoing transformation of Lotus.”

What the judges said:

“In a world in accelerated evolution, having variable platforms is win:win” – Marco Marelli

“Following the ups and downs of Lotus Cars in recent years has been like following a complex soap opera. Entertaining, but quietly exhausting. Meanwhile, Lotus Engineering has been steadfastly at work, doing what they do best: turning out innovations at the automotive engineering first-principles, someone-should’ve-done-this-before level. They continue to be a presence that’s impossible to ignore” – Phil Morse, Energy Balance

“What the Lotus team is doing at the moment, is like renewing the brand. Their biggest challenge is to enter the electric mobility era by keeping the brand’s core value, which is light weight. Finally the team is on a good path” – Juergen Zoellter

The rankings:

1: Lotus Engineering

2: Multimatic

3: McLaren Automotive

4: Williams Advanced Engineering

5: Jaguar Land Rover (JLR)

Innovation of the Year

This category recognises the best dynamics technologies integrated into the vehicle. The panel considered hardware, software, engineering and computing innovations that can be applied to advance and enhance vehicle dynamic setups.

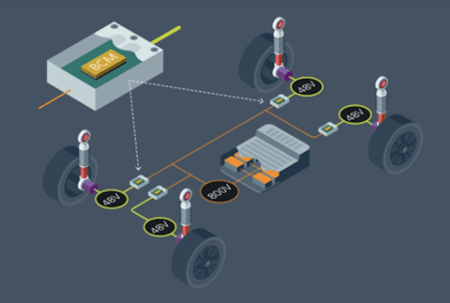

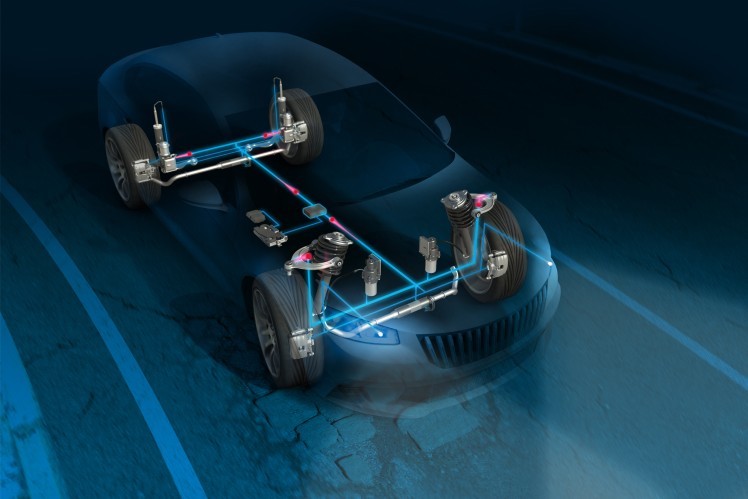

Winner: ZF smart chassis

The automotive world is heading towards greater levels of automation, with onboard sensors generating huge amounts of data, which algorithms can process to inform system updates and upgrades, , and even to enable new business models. ZF is working to capitalise on these advances, by combining chassis and sensor technologies to create intelligent chassis.

ZF’s engineers have developed a height-level sensor that can be integrated into a suspension control arm, which they say offers functional diversity and data-gathering capabilities that extend far beyond its original purpose. Instead of being installed separately in the body, the sensor is integrated into the chassis bearing, bringing advantages in terms of durability, cost, weight, ease of installation and versatility. The sensor supports various semi-active and active systems for chassis regulation, as well as dynamic headlight range adjustment.

The further advantage ZF is aiming for, that of new data-driven business opportunities, can begin with this component. The evaluation algorithms give sensors the intelligence they need to offer customers added value in different areas. The data the sensor collects yields information about the vehicle, its surroundings and the road surface, which can be valuable for commercial vehicle users and fleet owners, as well as for road infrastructure maintenance.

ZF is currently developing the software required for this advanced data analysis. For example, with its memory for disruptive road features, the sensor can capture the location of road defects or high kerbs, which can be recalled in later journeys, with the system then adapting the chassis accordingly to improve ride comfort and help avoid damage. The sensor can also detect differences in vehicle load, and thereby determine the relevant information to optimise electronic safety systems.

If the sensors become sufficiently widespread, the transport infrastructure could also benefit, as the analysed data could provide information about the condition of roads and bridges. Weak points such as cracks or potholes in the road surface could be detected and repaired much more quickly and efficiently in this way. Production of this smart chassis component is due to begin in 2023.

The rankings:

1: ZF Smart Chassis

2: Coventry University: Run Dry Traction System

3: University of Surrey: EV torque vectoring

4: Pirelli: Cyber Tyre

5: SRI: Sensing Core

“With cameras and sensors that can capture the location of road defects and high kerbs, driving enjoyment, comfort and also safety will reach new heights” – Marco Marelli

Development Tool of the Year

Developing a great dynamic setup requires great tools. This category celebrates the latest tools that help vehicle dynamics engineers evaluate their designs and setups to achieve automotive excellence.

Winner: Dynisma DMG-1

Dynisma Motion Generators (DMGs) have been designed for automotive manufacturers and suppliers to aid advanced vehicle development and testing, as well as for motorsport teams that want to optimise driver and car performance. Dynisma won with its DMG-1 model, and its associated lightweight DMG-1 Carbon version advanced driving simulators. These advanced driving simulator technologies allow OEMs and Tier 1 suppliers to conduct tests such as ride comfort, handling and tyre development, as well as complex and extreme vehicle dynamics and ADAS systems testing, in a virtual environment.

The launch customer for the simulator was certainly high profile, as earlier this year Dynisma revealed its first customer order for the motion simulator, a customised version developed in a two-year project for, and with, Scuderia Ferrari. The 360°simulator is claimed to have the lowest latency and the highest bandwidth motion cueing of any motion simulator available on the market. The simulator is being used to support the design phase of ‘674 project’, Ferrari’s 2022 Formula 1 car.

The company says its lightweight carbon composite version, the DMG-1 Carbon, delivers the lowest latency (sub 4ms) and highest bandwidth (>55hz in all 6DOF) of any simulator currently available on the market. This low latency ensures the driver is able to react faster to events such as oversteer, and the system’s high bandwidth facilitates motion cueing, accurately transferring a high level of information to the driver, which provides a realistic and responsive driving experience.

With environmental considerations coming to the fore, as well as test programme safety, the accuracy of such systems can help by reducing the requirements for physical testing, as well as saving time and budget.

The rankings:

1: Dynisma DMG-1

2: MegaRide: RIDEsuite

3: Applus IDIADA: dbBrake DAU

4: MB Dynamics: Model BHP/EPBTM

5: VI-grade: DiM400 Cable-driven Simulator

Test Facility of the Year

The panel considered the most impressive new developments at proving grounds and test tracks, as well as facilities offering the use of dynamics test equipment.

Winner: AstaZero

AstaZero is the world’s first full-scale independent testing and demonstration facility for future road safety, and it has now been expanded to house the world’s longest indoor track, some 700m-long and 40m-wide.

Named the AstaZero Dry Zone, the Swedish company says it will play an important role in the transition of the automotive industry toward self-driving and connected vehicles, and will provide opportunities for their research, development and validation, as well as the surrounding infrastructure.

Reproducible, well-controlled environments are essential for ensuring the accuracy of test results, and the AstaZero Dry Zone will enable tests to be carried out 24 hours a day, 365 days a year. Tests can be carried out repeatedly in the same light conditions and on the same surface, no matter the time of day or season. Active safety systems and autonomous technologies comprise the main focus areas, but vehicle dynamics and brake performance will also be tested on the new track.

AstaZero received increased interest in the facility when the pandemic hit and the subsequent travel restrictions made it difficult for the industry to conduct tests. The plans for the new track were then accelerated – a rare positive from the situation.

“New thinking here with the first full-scale independent test facility for future road safety. Built to be able to think with self-driving in mind, this facility may well be a go-to in the near future” – Carl cunanan, C!, Philippines

The rankings:

1: AstaZero

2: Applus IDIADA

3: SunTrax

4: Thyssenkrupp Bilstein

5: Testregion DigiTrans

The judging panel:

• Choi Joo-sik, Autocar Korea

• Robert Bielecki, Oponeo, Poland

• Christophe Congrega, L’Automobile Magazine, France

• Brian Cowan, freelance, New Zealand

• Carl Cunanan, C!, Philippines

• Padraic Deane, managing editor, Automotive Publications, Ireland

• Tarcisio Dias de Araujo, Mecânica Online, Brazil

• Jim Kenzie, Toronto Star, Canada

• Nikos Kounitis, 4Wheels, Auto Bild Hellas, Greece

• Nicol Louw, Car South Africa

• Marco Marelli, freelance, Italy

• Frank Markus, Motor Trend, USA

• Marc Noordeloos, freelance, USA

• Sergio Oliveira de Melo, El Informador, Mexico

• Alvaro Sauras Alonso, Autofacil and CAR&Tecno, Spain

• Mohamad Sheta, Al-Masry Al-Youm Newspaper, Auto Arabia, Middle East Auto News Agency

• Gábor Szécsényi, Az Autó and Retro Mobil, Hungary

• Oleg Vasilevsky, Auto Bild, Ukraine

• Adam Gavine, Vehicle Dynamics International, UK

• Hormazd Sorabjee, Autocar India

• Jürgen Zöllter – freelance, Germany

Panel changes for 2021

- Tomaz Porekar, Avto Magazin, Slovenia – Now retired. Thank you for your service, Tomaz

- Phil Morse – Energy Balance, USA – New panel member. Welcome Phil!