Mark Boyle, product manager at Amada Weld Tech, answers five key questions on the subject of automotive laser welding. Amada Weld Tech is a manufacturer of resistance welding, laser welding, marking, cutting, and micromachining equipment and systems.

What are the key automotive applications for laser welding, and when and why could laser welding be the best choice for these applications?

Within the automotive industry, there has been a huge increase in the use of laser welding in manufacturing. It is now commonplace for many automotive applications, including large-scale welding of body frames (body-in-white), door frames, trunks, auto hoods, and chassis; and laser plastic welding for front and back lights and electronic housings.

Sometimes forgotten since the welds are internal to automobiles and sometimes very small in size, laser welding is also being widely used for metal welding of many sub-components, including airbag initiators; motor coil windings; battery tab-to-bus bar connections for vehicle electronics; and electrical interconnections within an automobile build.

In the past, welding for these applications has been achieved using a variety of other technologies, including resistance welding (RW), tungsten inert gas (TIG or GTAW), and metal inert gas (MIG or GMAW). Lasers are taking the place of these technologies in many automobile welding applications, primarily because the process imparts less heat, resulting in more localised heat with a smaller heat-affected zone (HAZ). In addition, with the automotive industry moving towards lighter and more conductive material, it is easier to weld with laser welding than, for example, resistance welding (RW). Because laser welding imparts localised heat, operators can address smaller parts. Better accessibility and less restrictions to parts enhances design flexibility, enabling approaches that may not have been possible with other techniques.

Finally, other welding methods may leave visible weld marks on some parts, which can be a concern from a design or aesthetic point of view. With lasers, there is not as much heat and one is not providing as much of a heat signature, greatly increasing design flexibility.

What would you say are the trends that having the biggest impact on laser welding for the automotive market?

By far the biggest trend today is the electrification of motors, as evidenced by the increasing number of hybrids and all-electric automobiles on the streets today. These vehicles require welding of electric motor components, including powertrain connections and stator hairpins. Battery welding and battery connections are additional key applications in vehicle electrification. Welding is required to create the battery cell, join cells to create a module or pack, and sometimes connect the modules to create a complete battery assembly.

The connections in the electric motor and battery pack manufacturing are generally made of conductive materials, for which laser welding is suited. In addition, weld joints demand high strength, high conductivity, and high reliability in adverse conditions, meaning these welds should meet these criteria and be traceable.

Another trend favouring laser welding is the widespread increase of the use of electronics within vehicles compared to 20 to 30 years ago. Nowadays nearly everything is controlled by a computer; almost the only thing a vehicle operator can do by hand is refill the windshield wiper fluid!

Laser welding for electronics connections has earned a very high safety record. In addition, there is high throughput without a great deal of scrap, a factor that ties into improved economics for the laser-welding technique. This trend also includes the increase in vehicle safety equipment, especially advanced driver-assistance systems (ADAS), connecting sensor-based safety equipment. While some of the connections are made by reflow soldering – like flex circuit to PCB, often the sensor housings will be sealed via laser welding.

Finally, laser welding technology is well suited to high-speed production lines, particularly fibre lasers which have no consumables and no power degradation. These lasers form the backbone for new automotive production lines.

What type of laser welding equipment and technology is being used for automotive applications, and what are the advantages and disadvantages of current technology/equipment options?

A variety of laser technologies is being used, including pulsed neodymium-doped yttrium aluminium garnet (Nd:YAG) for small components, spot welds and seam welds; blue direct-diode lasers; fibre lasers; and pulsed disk lasers.

Fibre lasers have recently gained more of a foothold and are taking over applications across the board in the automotive industry. A fibre laser is generated within a flexible doped glass fibre that is typically 10 to 30 feet long and has a fibre core diameter between 10 and 50 microns in diameter. Ytterbium is used as the doping element because it provides good conversion efficiency and a near 1 micron output wavelength, which matches well with existing laser delivery components.

Available for applications requiring everything from a few watts to tens of kilowatts, fibre offers ease of use, handling, and longevity (if not damaged by mishandling). Fibres are also economical and relatively cheap to operate on the plant floor because they do not draw as much electricity as a YAG or pulsed disk laser.

What process do you use to consult with customers on their automotive application welding challenges?

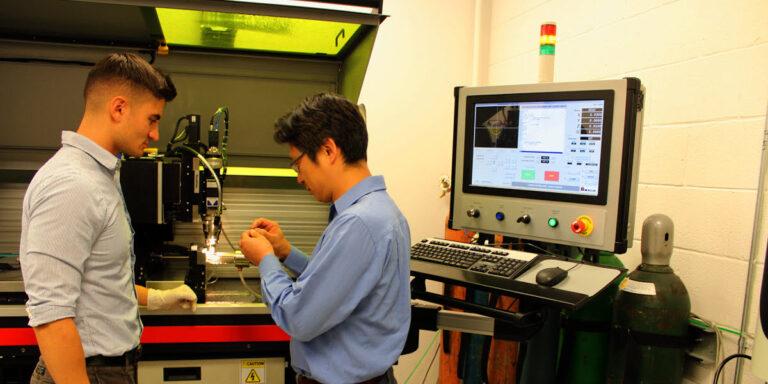

Customers send or bring in samples of parts for welding to our application technical centre, which is comprised of 25,000 square feet of lab space situated in an 85,000 square foot manufacturing facility. The technical centre is equipped with application-specific labs that support each of the company’s product lines and various joining technologies.

The experts in the application labs determine the solution that best fits the application – and budget. These application engineers provide options and develop a report with information showing how to join those two – across all technologies – as well as providing information on many different technologies and giving advice on what source would be best, helping customers select equipment for a robust process. By comparing and contrasting laser welding against resistance welding, micro TIG welding, and other platforms, applications experts help customers make informed decisions.

In addition to flexible technology selection, customers can see equipment options within the technology. On the laser processing side, the application labs have Nd:YAG and fibre welders. Resistance welding choices, for example, include AC, capacitive discharge, high frequency, and linear DC. For cutting and micromachining, customers can see system implementations showing exactly what would be purchased.

We have also noted interest in transitioning to laser welding and can help support customers transitioning into this technology.

Can you give us an example or examples of a recent challenging automotive application and describe the laser welding process that was developed to meet the challenge?

We have recently seen three interesting automotive industry applications: sealing of airbag initiators; tab-to-cell and tab-to-bus bar battery welding; and copper hairpin welding in an electric motor. Each of these applications can be achieved with a continuous wave (CW) fibre laser.

Airbag initiator

In the airbag initiator application, a seam weld is used to seal the gunpowder inside the initiator can. If a driver is in an accident, current is applied across the leads on the can with gunpowder, which heats up and explodes to start the process of opening the airbag. We have supplied a number of lasers for airbag initiator welding systems using both pulsed Nd:YAG and fibre laser technology. Over the last five to seven years, the industry has transitioned to fibre laser technology, which is a much faster process and increases throughput – the weld process is 10-times faster!

Tab-to-cell and tab-to-bus bar

Another growing market has been connections of battery cells, battery packs and battery modules. As hybrid and fully electric vehicles continue to increase in popularity, the demand for tab-to-cell and tab-to-bus bar battery welding will continue to increase. We have developed several solutions for joining the tab-to-cell and tab-to-bus bar.

As the industry has continued to develop, there has been a transition to using more conductive material for the tabs. However, the battery can’s material (if using cylindrical batteries) has not changed. We are now frequently requested to weld Cu to a cold rolled steel (CRS) can, or even worse, aluminium to CRS. New laser sources enable this joining of dissimilar metals.

For example, we have used 500 W-1,000W single mode continuous wave fibre laser micro welders to concentrate the energy into a small spot to aid energy coupling into the material and the resultant penetration. This new technique shows promise for joining dissimilar metals found in the tab-to-cell application.

In one case study, mechanical testing found peel strength to be good – after thermal soak and shock, 50 samples of the weld peeled within ±2 N. This narrow band of peel results shows the reproducibility and reliability needed in production. The high power allows for better connection of thicker tabs to the bus-bar.

Copper hair pin

It is now commonplace to use pins instead of the traditional copper winding found inside the electric motor stator as a way of improving engine performance. However, the pins are made of copper, which is a difficult material to weld. Copper has high reflectivity in the IR, so coupling into the material to create a melt pool requires significant energy density.

With the advancement of single-mode fibre lasers and scanning beam delivery systems, we have been able to successfully weld this challenging material and geometry. Depending on the size of the pins, anywhere between 1,000W and 4,000W are typically used. The key to success has been control of the melt pool and avoiding porosity.