A lightweight, road-legal track car from a small UK startup company – it’s a familiar story, and one which doesn’t always end in commercial success. However, what makes the Elemental Rp1 stand out as a credible new entrant to a surprisingly crowded market is the people behind it, a crack team of six that draws on experience from Porsche, AMG, Lotus, Airbus, and McLaren F1 and McLaren’s road car projects, among others.

Indeed Elemental’s technical director John Begley’s passion for vehicle handling and dynamics is matched by his know-how, with his CV including: chassis, suspension and aerodynamic design for the Nissan and Triple Eight race-winning BTCC cars; mechanical and aerodynamic development for the McLaren F1 team; and key roles in the McLaren Mercedes SLR, 12C and P1 programmes.

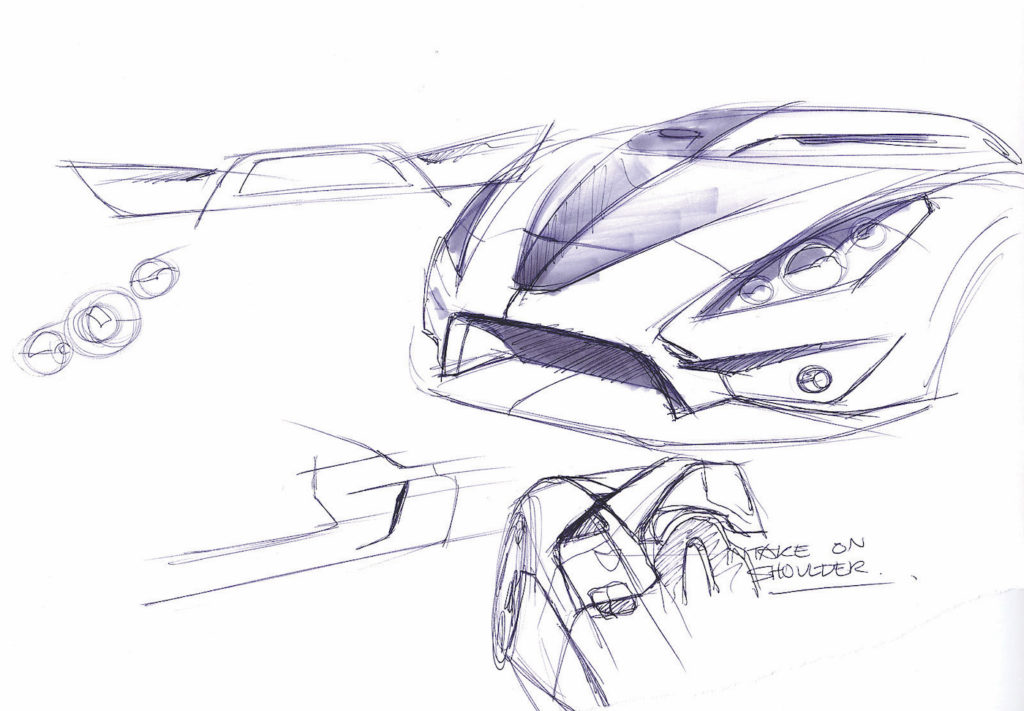

The dream of Begley and his team – who are largely ex-McLaren – is to create a track car that can realistically be driven from home to a track hundreds of miles away, with a dynamics setup that can be quickly adjusted to suit its environment.

At the heart of the Rp1 is a carbon-composite tub, which is exposed mid-ship to save weight and to indicate its sporting intent. The modular tub was developed in-house by resident composites guru Peter Kent, who drew upon his extensive F1 experience, with a little help from the UK government’s Technology Strategy Board. Key factors in the patent-pending design are light weight, strength, cost efficiency and production efficiency. To meet these aims, the tub design features aluminium strand panels, carbon-fibre moulded panels, an aluminium compound sandwich floor and bulkheads, and carbon composite sidewalls and thwart panel. The head bulkhead carries the mounting points for the front subframe, steering and stay, while the rear bulkhead is the mounting point for the rear subframe and volume hoops. Carbon composite is also used for the beautiful exposed central spine that stretches along the centre of the car, from the concealed radiator duct, through the tub between the driver and passenger, and all the way to the central exhaust outlet.

It’s a solid core, helping achieve a 620kg dry weight in the 2-litre prototype, which Begley expects to be reduced to 600kg once the structures, layout and materials have been optimized prior to production in early 2016. Early in the project, which began in 2012, GRP was considered for the bodywork, but was soon rejected in favour of carbon composites for reasons of weight and production quality.

Underpinning the tub is a suspension designed for ease of adjustability so an owner can optimize the damper settings, camber and ride height for the drive to the track; and for the track itself, using just a jack, spanners and sockets. This simple owner adjustability is seen as a key selling point of the car, and also extends to the seats, pedals and steering wheel.

The team opted for a double wishbone suspension, with a subframe-mounted, long arm setup at the front, and a gearbox mounted, spun-out arm setup at the rear, with Eibach springs and adjustable Nitron dampers.

Asked about the car’s handling characteristics, Begley says that with so much owner adjustability in the camber, castor and toe, it can be whatever the owner wants, with no compromise needed for road comfort or track performance.

“It’s race car mentality. The kinematics of the suspension give a very stable roll centre and linear camber curves so it is predictable and progressive toward the limit,” he says.

Further stability is created by the underfloor downforce dynamics – a claimed 200kg at 100mph – created by large front and rear diffusers. The aerodynamic floor was enabled by a feature that is also claimed to make the Rp1 a comfortable drive: an F1-style ‘feet up’ seating position, which freed-up space for the large front diffuser. The design also creates sufficient space between the two front diffuser outlets for the 54-litre fuel tank, which helps achieve near 50:50 weight distribution.

Speaking of weight distribution, the centre of gravity (CoG) of the car is located at the driver’s CoG. Given the car’s weight, the driver’s weight becomes an important factor in the car – especially given that a 6ft 6in driver can squeeze in – but by locating the CoG at that point, the balance of the car remains constant, even when a passenger is added, and when luggage, helmets or race suits are carried in the side pods.

That weight distribution remains constant, whichever of the two current engine options is fitted to the rear subframe’s ‘cassette’ longitudinal engine mounting system. The current prototype is powered by a Ford 2.0 litre EcoBoost engine, custom-tuned by AER/Life racing to produce 280bhp and mated to a Hewland 6-speed paddleshift sequential gearbox and LSD.

at various UK facilities

The other engine option – “for the time being”, says Begley, with a 999cc Honda Fireblade unit being mooted – is a 1-litre EcoBoost unit giving around 180bhp. The price will be the same for either – estimated at around £70,000 (US$106,000) – but the character will be quite different. Around 30-40kg is saved just through fitting the smaller engine, with further weight reductions expected to result from being able to fit smaller tires and brakes, and a little more weight bias added to the front.

So which version is Begley’s Rp1 of choice? “To be honest, I prefer the 1-litre, which can be more fun at lower speeds and has more character and feel.”

Begley explains the price parity is possible because the bill of materials is similar for both. “As a business case there is not much to gain by offering the 1-litre version cheaper. It’s more about the characteristics of the car,” he explains.

Final pre-production tests are underway at various facilities in the UK, with Elemental’s test and development driver David Pittard – also winner of the British Endurance Championship 2012 and a Ginetta GT4 Supercup competitor – reporting that the car is “mega”, having clocked 0-60mph in 3.1 seconds, 60-100mph in 4.4 seconds and 100-0 in 4.5 seconds at a recent track test.

Elemental says that several orders have already been placed, with production beginning in early 2016. According to Begley there will be further options in the future for a more track-focused version, with upgraded material options that can save further weight. These include using T45 for the subframe to reduce gauge size while maintaining torsional rigidity.