Researchers from Chalmers University of Technology in Sweden have developed a structural battery that performs a claimed 10-times better than previous versions of the technology. The innovative battery contains carbon fibre that serves as an electrode, conductor, and as a load-bearing material, which could enable essentially ’massless’ energy storage in vehicles.

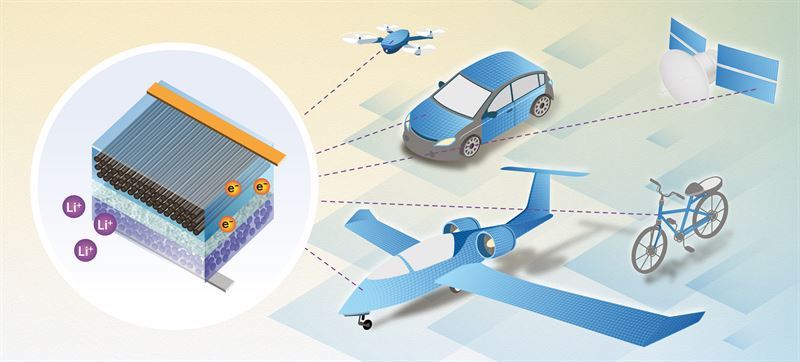

Put simply, a structural battery works as both a power source and as a load-bearing part of a structure, such as a car body. The Chalmers team refers to this design as massless energy storage, because in essence the battery’s mass ‘vanishes’ when it becomes part of the load-bearing structure. Calculations by the researchers show that this type of multifunctional battery could greatly reduce the weight of an electric vehicle, which would also yield potential benefits in terms of vehicle dynamics.

How it works

The scientists at Chalmers University of Technology have been researching and developing structural batteries since 2007, during which several previous discoveries have been made involving certain types of carbon fibre. In addition to being stiff and strong, the batteries are also effective in storing electrical energy chemically. Indeed in 2018 this work was named as one of the 10 biggest scientific breakthroughs of the year by Physics World.

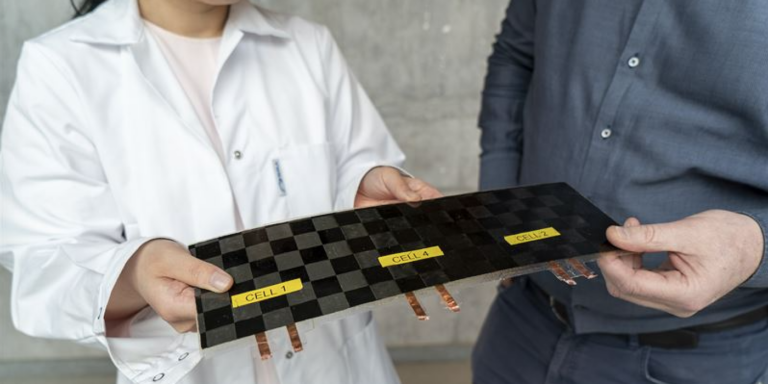

The researchers selected the materials with the aim of investigating and understanding the effects of material architecture and separator thickness on a structural battery. The battery uses carbon fibre as a negative electrode, and a lithium iron phosphate-coated aluminium foil as the positive electrode. The carbon fibre acts as a host for the lithium and thus stores the energy. Since the carbon fibre also conducts electrons, copper and silver conductors are not required, further reducing the weight.

Both the carbon fibre and the aluminium foil contribute to the mechanical properties of the structural battery, with the two electrode materials separated by a fibreglass fabric in a structural electrolyte matrix. The electrolyte transports the lithium ions between the two electrodes of the battery, and transfers mechanical loads between the carbon fibres and other parts.

The team have, until now, struggled to manufacture batteries that have both good electrical and mechanical properties. However, they say the development programme has taken a big step forward, with some help from a collaboration with KTH Royal Institute of Technology in Stockholm (which developed the electrolyte), with the latest version of the structural battery having properties that far exceed anything yet seen in terms of electrical energy storage, stiffness and strength. Indeed the researchers say the multifunctional performance is some 10-times higher than their previous structural battery prototypes.

The battery has an energy density of 24 Wh/kg, which is around 20% of the capacity of comparable lithium-ion batteries. However, since the weight of an electric vehicle fitted with such batteries can be greatly reduced, less energy will be required to drive the car, and the lower energy density also results in increased safety. With a stiffness of 25 GPa, the Chalmers team say their structural battery can really compete with many other commonly used construction materials.

“Previous attempts to make structural batteries have resulted in cells with either good mechanical properties, or good electrical properties. But here, using carbon fibre, we have succeeded in designing a structural battery with both competitive energy storage capacity and rigidity,” explained Leif Asp, Professor at Chalmers and leader of the project.

Applications: electric bikes, cars, aircraft and consumer electronics

A new project, financed by the Swedish National Space Agency, is currently underway, which could see the performance of the structural battery increased even further. The aluminium foil will be replaced with carbon fibre as a load-bearing material in the positive electrode, increasing both stiffness and energy density. The fibreglass separator will be replaced with an ultra-thin variant, which will give a much greater effect – as well as faster charging cycles. The project is expected to be completed within two years.

Leif Asp, who is also leading this project, estimates that such a battery could reach an energy density of 75 Wh/kg and a stiffness of 75 GPa. This would give the battery a similar strength to aluminium, but with a comparatively much lower weight.

“The next-generation structural battery has fantastic potential. If you look at consumer technology, it could be quite possible within a few years to manufacture smartphones, laptops or electric bicycles that weigh half as much as today and are much more compact”, stated Asp.

And in the longer term, electric cars, electric airplanes and satellites could be designed with and powered by structural batteries.

“We are really only limited by our imaginations here. We have received a lot of attention from many different types of companies in connection with the publication of our scientific articles in the field. There is understandably a great amount of interest in these lightweight, multifunctional materials,” added Asp.

The research partners

The structural battery project is run in collaboration between Chalmers University of Technology and KTH Royal Institute of Technology, Sweden’s two largest technical universities, with the battery electrolyte developed at KTH. The project involves researchers from five different disciplines: material mechanics, materials engineering, lightweight structures, applied electrochemistry, and fibre and polymer technology. Funding has come from the European Commission’s Clean Sky II research programme, as well as the US Air Force.