NVH testing has never been more essential, as hybrids and electric vehicles (EVs) operate with near-silent electric motors, making even subtle noises from road, suspension and wind far more noticeable.

LABA7 has addressed these challenges with the Electromagnetic Actuated Damper Test System (EMA). The system comes rich with innovative features, extensive customisation options, and a focus on precision.

When testing the noise levels emitted by dampers, the testing system itself must operate in near silence. The EMA achieves this with a low noise level of just 50dB, comparable to a quiet office.

Unlike traditional hydraulic systems, the EMA has minimal moving parts – only the linear bearings within its housing – making it exceptionally quiet. Smart algorithms further reduce operational noise, creating an ideal testing environment. This is especially important for EVs, in which unique factors like weight distribution and regenerative braking can amplify vibration challenges.

“We have designed the EMA to test in silence, which is critical when evaluating how dampers respond without interference,” says Andrius Liškus, CEO of LABA7. “However, our focus doesn’t end with noise reduction. The EMA is equipped with a couple of solutions that are the first in the world, particularly in terms of data sampling, accuracy, and power supply”

Data sampling and accuracy

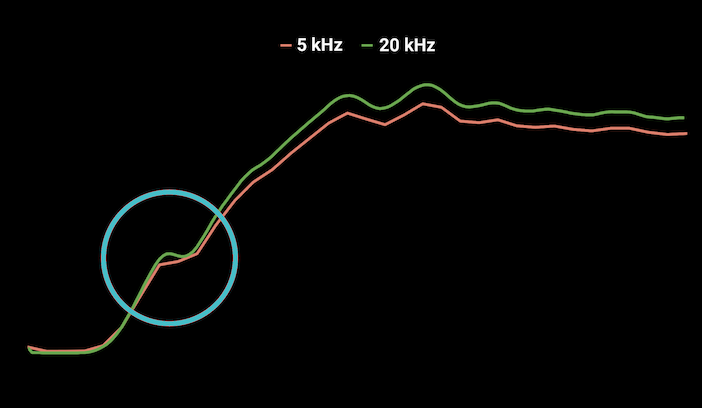

One of the standout features of the EMA is its in-house-developed controller, which integrates the control unit and data logger into a single, streamlined design. This setup allows closed-loop testing while the system samples synchronised position and force data at 20kHz or higher, virtually eliminating phase shifts and ensuring exceptional data accuracy.

“While the data recording speed is impressive, the level of resolution we have achieved is equally remarkable,” says Liškus.

The EMA can replicate and detect position changes as small as 50 nanometers, capturing even the tiniest variations in damper performance. The precise and repeatable results enable engineers to fully understand a damper’s response, supporting high performance standards and enhancing ride quality and safety.

Power supply system

Unlike traditional electromagnetic shock dynos that require high voltage and a specialised infrastructure, the EMA uses a supercapacitor-based energy storage system. This allows the system to operate on standard three-phase 16A inputs and, with optimisation, on standard single-phase power.

As a result, the EMA can be easily installed in a range of testing facilities, even remote sites where high-voltage setups are impractical or impossible. This efficiency lowers installation costs and makes the EMA accessible for a broader range of applications.

Software

The EMA’s user-friendly software is designed to maximise functionality and ease of use. Its intuitive interface shortens the learning curve, allowing teams to begin testing quickly.

The software supports traditional waveform tests such as sine, triangle, square and pulse, as well as track data and advanced random tests, like pink noise. Pink noise tests are generated based on frequency, duration, and stroke inputs, allowing engineers to simulate damper noise and vibrations at precise intervals.

“Our system’s ability to handle both high- and low-frequency vibrations ensures a thorough analysis of damper performance,” explains Liškus. This detailed NVH data enables engineers to design components that improve comfort and noise control.

The software also offers editing tools for track data imported from telemetry devices, allowing operators to zoom-in on specific segments and assess damper performance in real-world conditions. For post-testing analysis, features like overlay graphs make it easy to identify performance trends.

EMA integrates seamlessly with up to 12 external analogue sensors (expandable upon request), providing a complete picture of damper performance.

Not only can test data be imported directly into MATLAB for advanced analysis and modeling, but LABA7’s software also enables seamless integration with MATLAB workflows, giving engineers a powerful toolkit for post-processing and custom evaluations.

Custom features

LABA7’s commitment to customisation ensures that the EMA meets specific customer needs. Whether manufacturers require sideload testing, multi-axis testing, or other tailored configurations, LABA7’s team adapts the hardware and software for a range of specialised requirements.

Application across industries

Looking forward, LABA7 has ambitious plans. “We’re not stopping here. We’re moving further into NVH for aerospace, railways, heavy machinery, and other industrial applications,” Liškus adds.

With the EMA system, LABA7 offers a versatile, accurate and accessible solution for comprehensive damper and NVH testing, setting new standards for precision and adaptability across the vehicle manufacturing industry and beyond.

The EMA embodies LABA7’s mission: to advance testing solutions that drive quality and innovation in suspension design, NVH analysis, and beyond.

Find out more from LABA7