McLaren Automotive has collaborated with California-based industrial digital manufacturing company, Divergent Technologies, to design and engineer the advanced suspension hardware for its latest supercar, the McLaren W1.

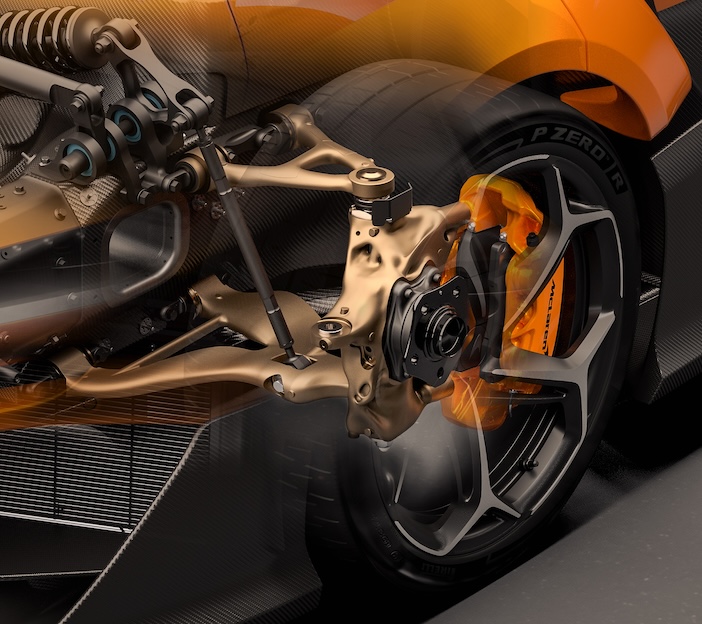

Launched earlier this month, the McLaren W1 is the successor to two iconic supercars– the McLaren F1 and P1 – and has been created according to the McLaren ethos of class-leading performance. The W1 features a Formula 1-inspired front suspension, which is mounted directly into the Aerocell carbon fibre monocoque.

Divergent’s additive manufacturing technology has been used in McLaren’s development of efficient and complex suspension systems to ensure optimal durability and stiffness in the W1, which include the front upper wishbone, aero form lower wishbone and front upright. The externally visible front wishbones are 3D-printed by Divergent.

According to Divergent, its innovative methods of designing and manufacturing have allowed McLaren’s engineers to rapidly iterate designs to progress development of the supercar’s structural suspension components.

“We are thrilled to have partnered with Divergent, a company that shares McLaren’s dedication to innovation in manufacturing and engineering. This cutting-edge technology has enabled us to develop more complex suspension structures in the McLaren W1, which enhance the driving experience for our customers and support McLaren’s mission to continually push the boundaries of performance,” stated Michael Leiters, chief executive officer of McLaren Automotive

“The suspension hardware designed and manufactured by Divergent has enabled the McLaren team to push the boundaries of what is possible in this digital manufacturing age of supercar production,” added Kevin Czinger, founder, chairman & CEO of Divergent.