BorgWarner has announced that Polestar and another “major European OEM” are launch customers for its electric Torque Vectoring and Disconnect (eTVD) system for battery electric vehicles (BEVs).

The eTVD is part of BorgWarner’s range of electric torque management systems (eTMS), designed to intelligently control wheel-torque to increase stability, enhance dynamic performance, and improve traction during launch and acceleration. The eTVD is currently in production on the Polestar 3 SUV, and production for the as-yet unnamed European OEM will follow later this year.

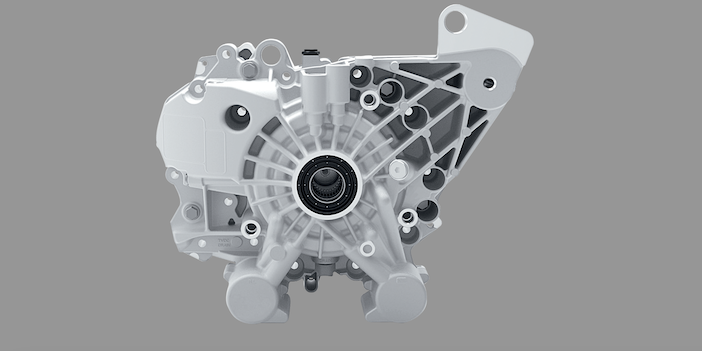

The eTVD is a three-in-one system, replacing the differential and featuring both torque vectoring and an on-demand disconnect function. In contrast to brake-based systems, torque vectoring prevents unnecessary brake interventions, thereby reducing harshness and vibration. This also leads to less wear and tear on brakes and tyres, with the added benefit of lower particle emissions.

The higher weight of BEVs compared with combustion-powered cars can reduce agility, but BorgWarner says its eTVD systems enable a much lighter feel of the vehicle while increasing overall safety. The intuitive software minimises the risk of undesired driving characteristics and enables traction regardless of road and weather conditions, while torque response is instantaneous in challenging and demanding scenarios. The software and controls of the eTVD systems can be customised by OEMs to align with their own platform needs and specific brand characteristics.

“With the market transitioning to more software-defined modules and vehicles, it is critical to have sophisticated systems in place, like our eTVD, that can precisely and quickly calculate, predict and control vehicle behaviour across a wide range of situations,” said Volker Weng, VP of BorgWarner Inc. and president and general manager of BorgWarner Drivetrain and Battery Systems.