Carbon fibre-reinforced plastics (CFRPs) are lightweight, strong and durable, bringing mass-reduction benefits for sectors such as automotive and aerospace. However, time-consuming experiments are required during the design phase of vehicles with CFRP structures, which is expensive.

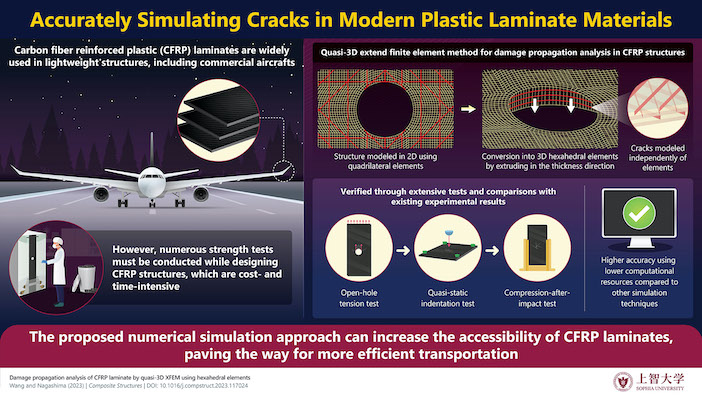

In a recent study by Sophia University in Tokyo, Japan, researchers have developed a quasi-3D extend finite element method, a computationally efficient approach to simulate damage propagation in CFRP laminates. The team say the method could make CFRP laminates more accessible for more projects such as car designs.

The pros and cons of CFRP

Many designers and engineers are looking for structural materials that are lighter weight than conventional materials such as steel or aluminium, without any reduction in strength. CFRP is one of the most popular materials available today that addresses this need, due to their low weight, high durability, and exceptional mechanical performance. These plastics are made up of tiny, yet extremely strong threads of carbon atoms held together by a plastic matrix.

However, designing CFRP laminates can be a very time-consuming. Engineers must run multiple strength tests to benchmark CFRP specimens whenever they adjust a given design. These tests drive up the cost of the final product and can hinder the application of CFRP.

Numerical simulation of damage propagation in CFRP

Against this backdrop, two researchers – Dr Chenyu Wang, a former PhD student at the Graduate School of Sophia University, and Professor Toshio Nagashima from Sophia University – have developed a novel method to conduct numerical simulations of damage propagation in CFRP laminates.

The researchers based their approach on a quasi-3D version of the extend finite element method (XFEM). In FEM, a structure or material is divided into small sub-regions known as elements, followed by the solving of physical equations for each element, to determine the overall response of the system. The ‘extend’ version, which has been used in this study, adds functions that capture local effects around discontinuities, enabling more accurate modelling of damage propagation in form of crack growth.

Notably, since CFRP laminates are made of stacked layers of material, modelling them as flat planes (two-dimensional or 2D) would fail to capture anomalies such as delamination. In contrast, a three-dimensional (3D) FEM simulation would be computationally intensive and complex to set up. To overcome these issues, the researchers took a balanced approach.

Wang and Nagashima first modelled the desired CFRP laminate as a 2D structure composed of quadrilateral finite elements and marked the position where cracks might occur. They then projected this structure in the thickness direction, while the models used to simulate delamination and matrix crack were automatically generated through their simulation system. The team say the strategy made the computations manageable, and the modelling to simulate CFRP damage more easy and efficient.

Physical testing

To verify the validity of their approach, the researchers ran simulations of three different strength and damage propagation tests on CFRP laminates and compared their results with the experimental data reported in other studies. The first was an open-hole tension test, in which a CFRP laminate with a circular hole in the middle was pulled from one end while the other end was anchored.

The second was a quasi-static indentation (QSI) test, during which a hard semi-sphere was pressed slowly and steadily against a CFRP laminate. The third and final test was the compression-after-impact test, in which the damaged specimens from the QSI test were subjected to a compressive force to assess their integrity and damage tolerance.

Overall, the researchers say the results of the proposed simulation method agreed well with the experimental data, outperforming the existing quasi-3D XFEM-based techniques.

Confident about the potential of the novel approach, Dr. Wang remarked: “The applications of composite materials such as CFRP will become more extensive and efficient if the results of this study are utilised in related fields.”

Wang also believes the widespread adoption of CFRPs can have ecological benefits. “In the future, if the damage of composite materials can be predicted more efficiently and accurately via numerical simulations, their cost will decrease. If these lightweight and high-strength materials are further applied in transportation, it will have a positive impact on energy savings and environmental protection.”